- Home

- About Us

-

Industries

-

Resources

- Contact Us

Your Guide to On-Demand 3D Printing

Published on: June 02, 2025

By: The Simple Machining Team

3D printing has become one of the most versatile and accessible tools for rapid prototyping and low-volume production manufacturing, allowing creators to iterate unique designs at unprecedented speeds. At Simple Machining, our on-demand 3D printing services are designed to augment your workflow and streamline any stage of the product development cycle.

What Is On-Demand 3D Printing?

On-demand 3D printing refers to the ability to upload a design file and receive a cost-effective physical part within days, sometimes even the very next day. This eliminates the need to invest in machinery, manage material inventory, or commit to high-volume production.

With just a few clicks, you can upload a model, select your material, get an instant quote, and place your order. Behind the scenes, we take care of slicing, print preparation, quality control, and shipping. Whether you need one part or one hundred, the process is the same—fast, flexible, and reliable.

Why 3D Printing is Ideal for Rapid Prototyping & Low-Volume Production

When speed and adaptability are top priorities, 3D printing delivers unmatched advantages. Unlike traditional manufacturing methods that rely on molds, dies, or fixtures, 3D printing allows you to manufacture parts directly from your digital file with minimal lead time. This makes it an ideal fit for rapid prototyping, where feedback cycles are fast and changes are frequent.

Instead of committing to large volumes or investing heavily in tooling upfront, you can order one part, assess its performance or fit, and quickly make design revisions before moving forward. When you are ready for a larger batch, 3D printing can quickly scale to meet project needs.

Additive Materials & Technologies

No two projects are the same, which is why material selection matters. Several materials exist to meet a broad spectrum of needs, from basic concept models to engineering-grade functional parts. Different 3D printing technologies serve different purposes, and selecting the right one can significantly impact the performance, cost, and appearance of a part.

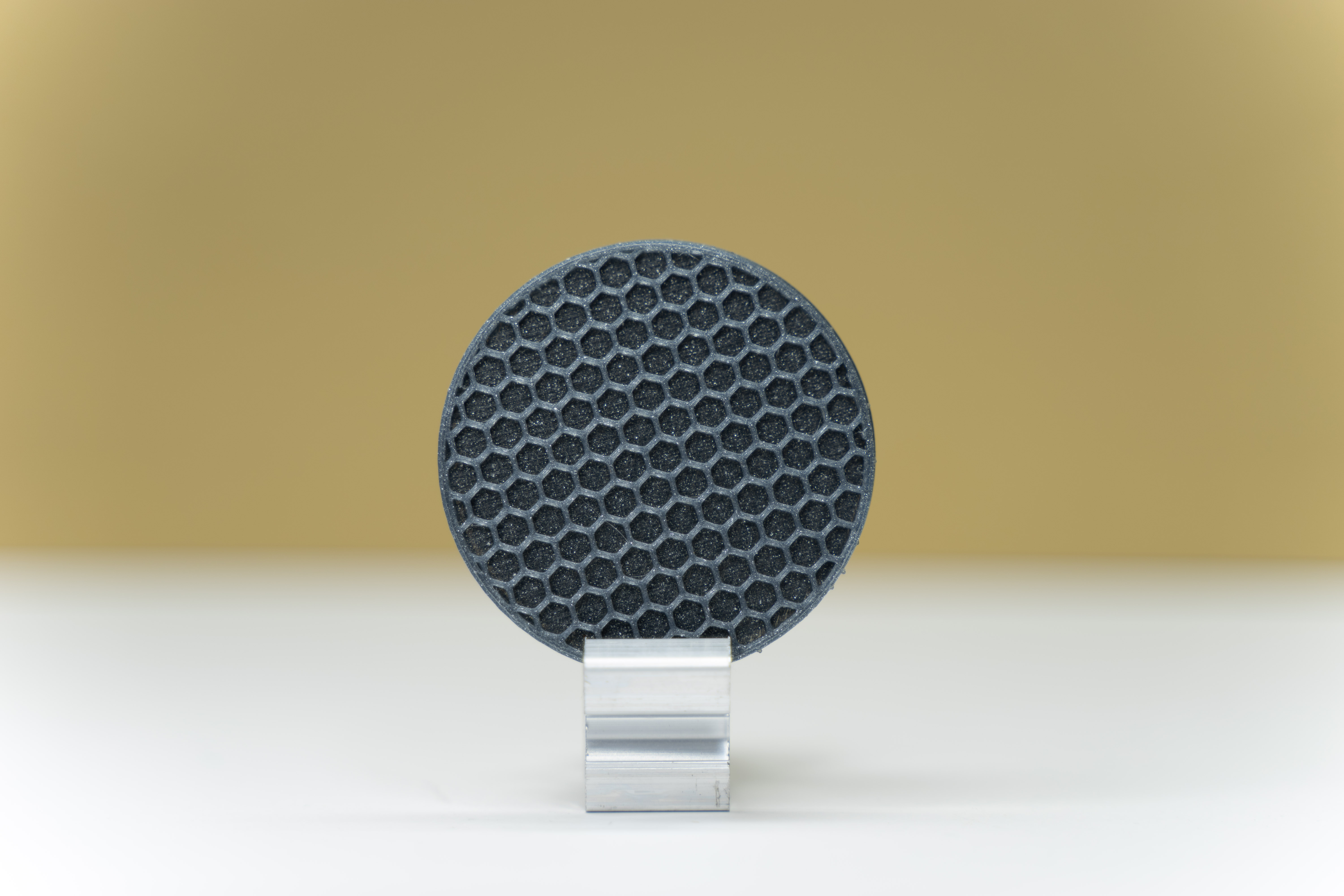

Learn more about FDM 3D Printing infill types

Fused Deposition Modeling (FDM) is one of the most common and cost-effective methods for producing strong, functional plastic parts. It works by extruding and stacking layers of melted thermoplastics. This technique is compatible with diverse materials such as PLA, ABS, ASA, carbon fiber-reinforced PLA, and flexible TPU. This process is ideal for draft prototypes, non-load-bearing models, and the quickest single quantity turnarounds.

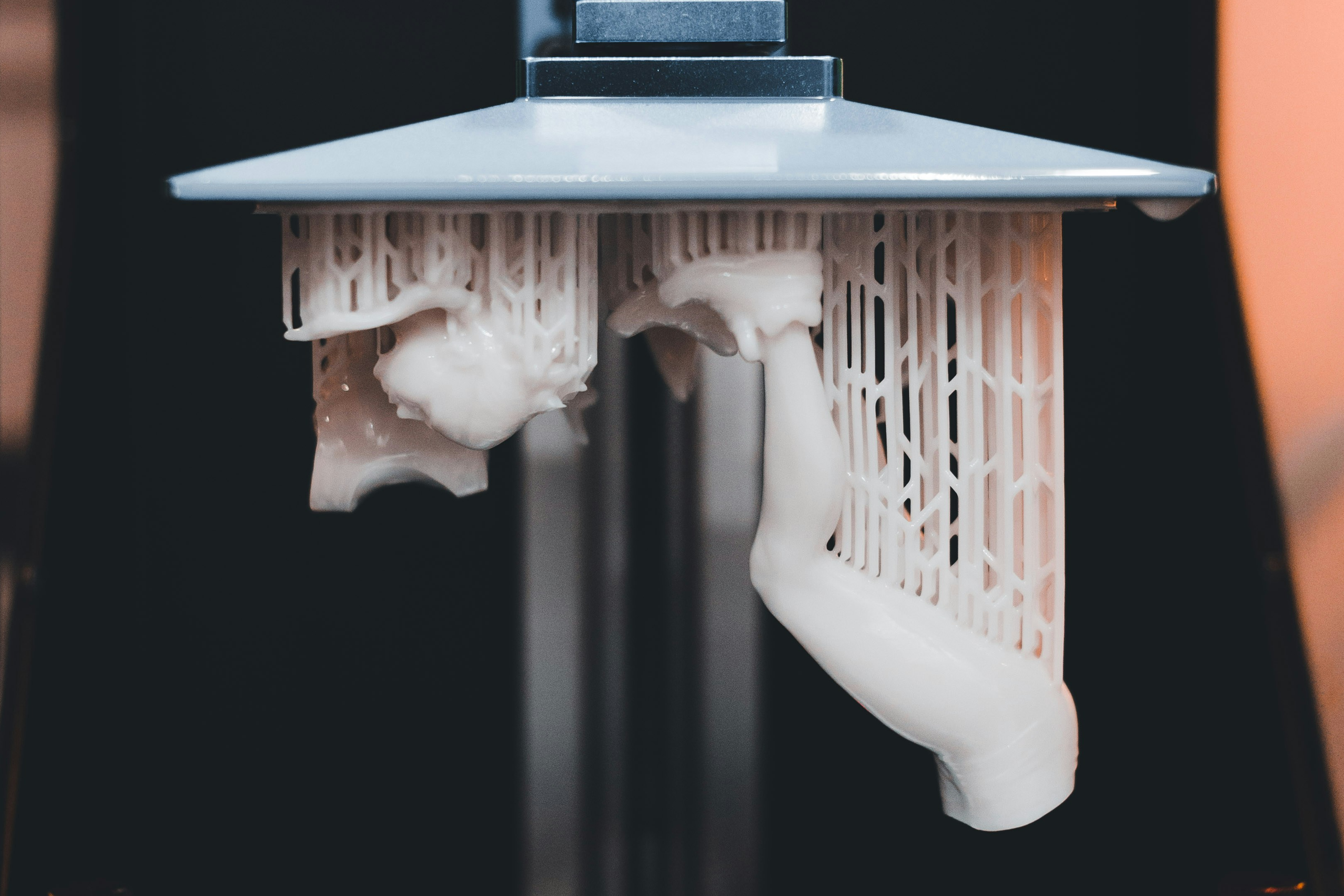

Stereolithography (SLA) is a method that excels in surface finish and fine detail. It uses a UV laser to cure liquid resin into hardened plastic with precision down to 25µm layer heights. SLA is best suited for visual prototypes, models requiring tight tolerances, or parts with intricate surface features. This additive method also lends itself to materials with unique performance such as water resistant Watershed X101c and UL-V0 rated flame retardant resins.

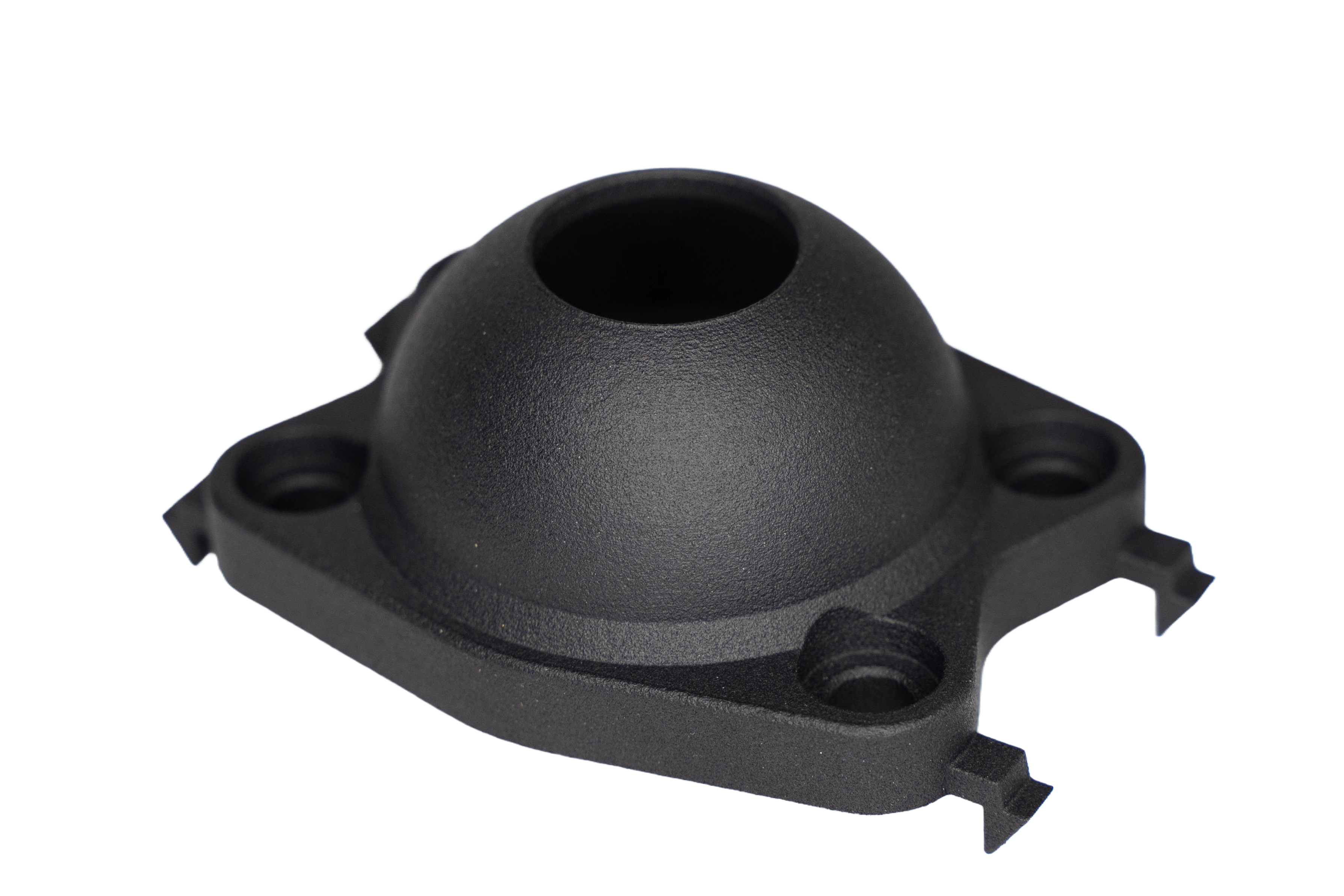

Selective Laser Sintering (SLS) is a powder-bed fusion technology that uses a high-powered laser to sinter thermoplastic powders. The process does not require support structures, enabling complex interlocking parts such as live hinges to be printed in a single build. SLS parts typically exhibit excellent mechanical strength and durability, making the process ideal for functional prototypes and end-use components. Common materials include Nylon PA12 and PA11, both valued for their toughness, thermal resistance, and dimensional stability.

Multi-Jet Fusion (MJF) is another powder-bed technology, but instead of using a laser, it employs inkjet-like heads to deposit a fusing agent onto the powder bed, followed by infrared heating to solidify the thermoplastic. This method allows for precise thermal control and faster build times compared to SLS. MJF parts feature consistent surface quality, high detail resolution, and strong mechanical performance. Like SLS, MJF works especially well with Nylon PA12 and PA11, offering a combination of flexibility, heat resistance, and impact strength suitable for end-use parts and small-scale production. For small batch projects, MJF tends to scale the best of the methods in both lead time and therefore pricing.

Choosing the right technology involves evaluating design complexity, material requirements, intended use, and budget. Each process offers a unique balance of speed, resolution, mechanical performance, and design freedom. To learn more about our 3d printing service, you can visit our 3D Printing Services Page.

Not sure which process to choose? Read our comparison article WITH recommendations!

From CAD to Quote: What to Expect

We’ve built our platform to make ordering parts as simple as possible. Once you have a CAD model ready, typically in STL or STEP format, just upload it to our quoting tool. You’ll see real-time pricing based on your selected material, quantity, and production speed, including volume-based discounts.

There’s no need to wait hours or days for a response. Our quoting engine is available 24/7 to quote and compare different material options, lead times, and pricing.

When you’re ready, just place your order and we will take care of the rest. Upload, quote, click to order. It’s manufacturing without the friction. If at any point, you get stuck, have a question, or just would like some guidance, all accounts are assigned a dedicated manager to support with any needs.

Applications & Industries We Support

The power of 3D printing lies in its versatility. Our customers span over 15+ industries from consumer products to healthcare, each using our services to prototype, test, or manufacture with precision and speed.

Functional prototypes can verify fit, evaluate strength, or test assembly interactions in engineering and product development. Industrial designers often use SLA prints for polished presentation models, and medical researchers turn to FDM and SLS to develop housings or enclosures for testing and iteration.

Educational institutions use our services to produce physical models for labs, demonstrations, and research tools. To help foster education and growth, we offer a standard 10% discount for all .edu email accounts. For our entrepreneurial customers bringing a new product to market, being able to prototype, refine, and launch without heavy tooling investment at each iteration can be the difference between shipping and stalling.

Whether you're a solo entrepreneur or an engineer on a product team, our goal is the same: to help you go from idea to product faster than ever before.

Ready to get started? Upload your model and get an instant quote.

Key Takeaways

- On-demand 3D printing offers fast, flexible production without tooling or volume commitments—ideal for prototypes and small runs.

- Simple Machining provides instant quoting, a wide range of materials, and dedicated support for every project.

- Material and process selection depends on design needs, performance requirements, and budget.

- Industries served include engineering, product design, healthcare, education, and startups—anywhere speed and precision matter.

Looking for more insights?

Sign up for the newsletter:

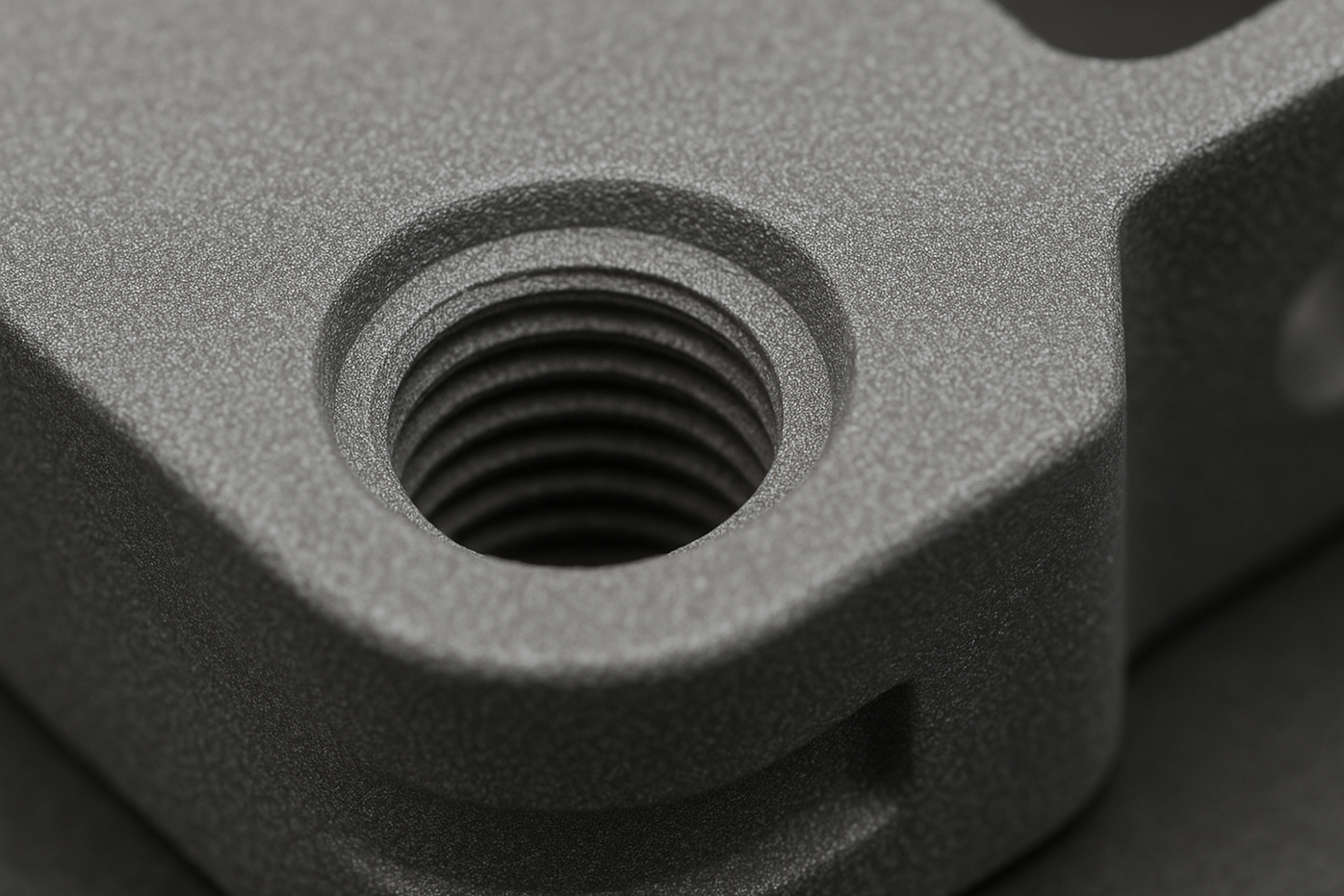

Designing Threads for SLS PA12: Pitch, Engagement, Reliefs, and Finishing

Read the Article 6 minute read

6 minute read

November 3rd

November 3rd

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th