- Home

- About Us

-

Industries

-

Resources

- Contact Us

Is MJF Right for Your Project? Everything You Need to Know

Published on: July 14, 2025

By: The Simple Machining Team

Multi-Jet Fusion (MJF) has rapidly gained traction among engineers and product developers seeking fast, repeatable 3D-printed parts. As design cycles accelerate and low-volume production becomes more common, understanding where MJF fits can make a meaningful difference in time-to-market and part performance.

In this guide, you'll learn:

- What MJF is and how it works: Explore the fundamentals of Multi Jet Fusion, including its history and core mechanics.

- When to use MJF: Understand the best applications for prototyping, short-run production, and spare parts.

- How MJF compares: See how MJF stacks up against FDM, SLA, SLS, and CNC machining.

- How to design for success: Learn tips for achieving better quality and efficiency from your MJF parts.

- Why outsource with Simple Machining: Discover how we simplify the process and offer expert-backed production starting at $30.

What Is Multi-Jet Fusion (MJF)?

Multi-Jet Fusion is an industrial powder bed fusion 3D printing process developed by HP. Unlike Selective Laser Sintering (SLS), MJF uses an inkjet array to deposit fusing and detailing agents onto a bed of nylon powder, then an infrared source fuses the agents into a final part. This produces highly detailed, isotropic parts with good surface finish and mechanical strength.

Common materials include PA12 for general-purpose parts, PA11 for ductile applications, and TPU for flexible components. All offer solid durability and chemical resistance, making them suitable for functional use.

HP’s role in advancing the technology through its HP 3D printers, especially the HP Multi-Jet Fusion printers, has cemented MJF’s place in modern manufacturing workflows.

A Brief History of MJF Printing

HP introduced Multi-Jet Fusion to the market in 2016, disrupting traditional 3D printing with a faster, more scalable powder bed fusion technology. Instead of legacy laser-based systems, MJF introduced infrared heating and chemical agents to dramatically increase print speeds and part consistency.

Over the years, HP has iterated on the platform with its Jet Fusion 5200 and 5600 series, designed to meet industrial prototyping and production standards. Learn more about HP’s advancements directly from their site.

Why Engineers Choose MJF for Prototyping

Rapid Build Times

MJF builds full layers in a single pass, allowing entire trays of parts to print in about 24 hours from start to finish. Compared to point-by-point laser systems, this significantly reduces turnaround time for design iterations and functional testing.

High Fidelity

MJF produces parts with layer thickness as fine as 80 microns (0.003”) and has a recommended minimum feature resolution of 1.0 mm (0.040“). Combined with uniform strength of up to 48 MPa across all axes, MJF delivers prototypes that closely match the performance and appearance of injection-molded parts.

Material Efficiency

More than 80 percent of unused powder can be recycled for future builds. With high packing density and minimal support waste, MJF supports cost-effective prototyping without sacrificing speed or quality.

Materials for MJF: PA12, PA11, and TPU

MJF is designed to print high-performance nylon-based polymers that balance strength, accuracy, and chemical resistance. Here's a breakdown of the most common materials:

PA12 (Polyamide 12)

Best for rigid, precise parts like enclosures, mounting fixtures, brackets, and housings. PA12 is the go-to MJF material due to its balance of stiffness and detail, while also supporting fine feature resolution with consistent layer bonding.

PA11 (Polyamide 11)

More ductile than PA12, PA11 is well-suited for impact-resistant or load-bearing applications, including living hinges, snap fits, wearables, and automotive clips. It’s also bio-compatible, making it a strong candidate for low-contact medical applications.

TPU (Thermoplastic Polyurethane)

TPU offers rubber-like flexibility, ideal for shock absorbers, seals, gaskets, and grips. It requires adjusted nesting and post-processing and is best for when elasticity and wear resistance are key.

Want help choosing the right material for your part? Reach out and our team is happy to help!

Is MJF Right for Low-Volume Production?

MJF isn't just for prototyping. With short lead times and strong parts, it is well-suited for production runs in the 50–500 unit range.

Bridge Production with MJF: Ideal for interim manufacturing while tooling is being finalized.

Custom Configurations and Variants: MJF is perfect for producing low-run variations without retooling or overhead costs.

Digital Spare Parts: MJF enables on-demand printing of spare parts, supporting lean inventory strategies.

Explore our CAD services or get a quote for other 3D printing options

MJF vs. SLS: Key Differences That Matter

The difference between MJF and SLS is in their fusion methods. MJF uses fusing agents and infrared energy to uniformly bond layers in one pass, while SLS relies on a high-powered laser to sinter each section point by point. As a result, MJF offers smoother finishes, more consistent isotropic strength, and faster build times.

SLS may have a wider array of specialty materials, but MJF shines in applications that demand scalability and surface quality. For many product developers, MJF strikes a better balance between cost, speed, and performance.

Comparing MJF to Other Manufacturing Processes

Compared to Fused Deposition Modeling (FDM), MJF delivers significantly better surface quality, mechanical strength, and dimensional accuracy. While FDM is cost-effective for very simple parts or conceptual models, MJF excels in producing end-use components that need tight tolerances and clean aesthetics.

When stacked against Stereolithography (SLA), MJF offers better mechanical durability and thermal resistance. SLA is ideal for extremely high-resolution visual prototypes but lacks the toughness required for functional applications. MJF, by contrast, balances detail with robustness.

Want to learn more about SLA? Read our blog: SLA 3D Printing Guide: Materials, Use Cases, and 6 Design Guidelines for Project Success

Against traditional CNC machining, MJF stands out for design freedom and no-tooling startup. CNC still offers unmatched precision for metal and tight-tolerance parts, especially in high-stress or heat-intensive environments. However, MJF enables more geometric complexity and often shorter lead times for polymer components.

Every process serves a unique purpose. MJF excels in situations demanding a blend of speed, functionality, and moderate production volumes. It surpasses most additive manufacturing techniques in part throughput and outperforms subtractive methods in terms of agility.

Read more about our comparison guide of FDM, SLA, SLS, and MJF with our recommendations to choose the right process for your project!

MJF Post-Processing: Choosing the Right Finish

Once your part is printed, post-processing can significantly impact its appearance, performance, and fit. Here’s how to choose the right MJF finishing option based on your project’s functional and visual requirements.

Bead Blasting: Removes residual powder and improves surface consistency.

Dyeing: Adds uniform color throughout the part for improved aesthetics and can enhance UV stability and surface durability.

Vapor Smoothing: Enhances surface finish for aesthetic or aerodynamic needs by chemically melting the outer layer to create a glossy, sealed surface.

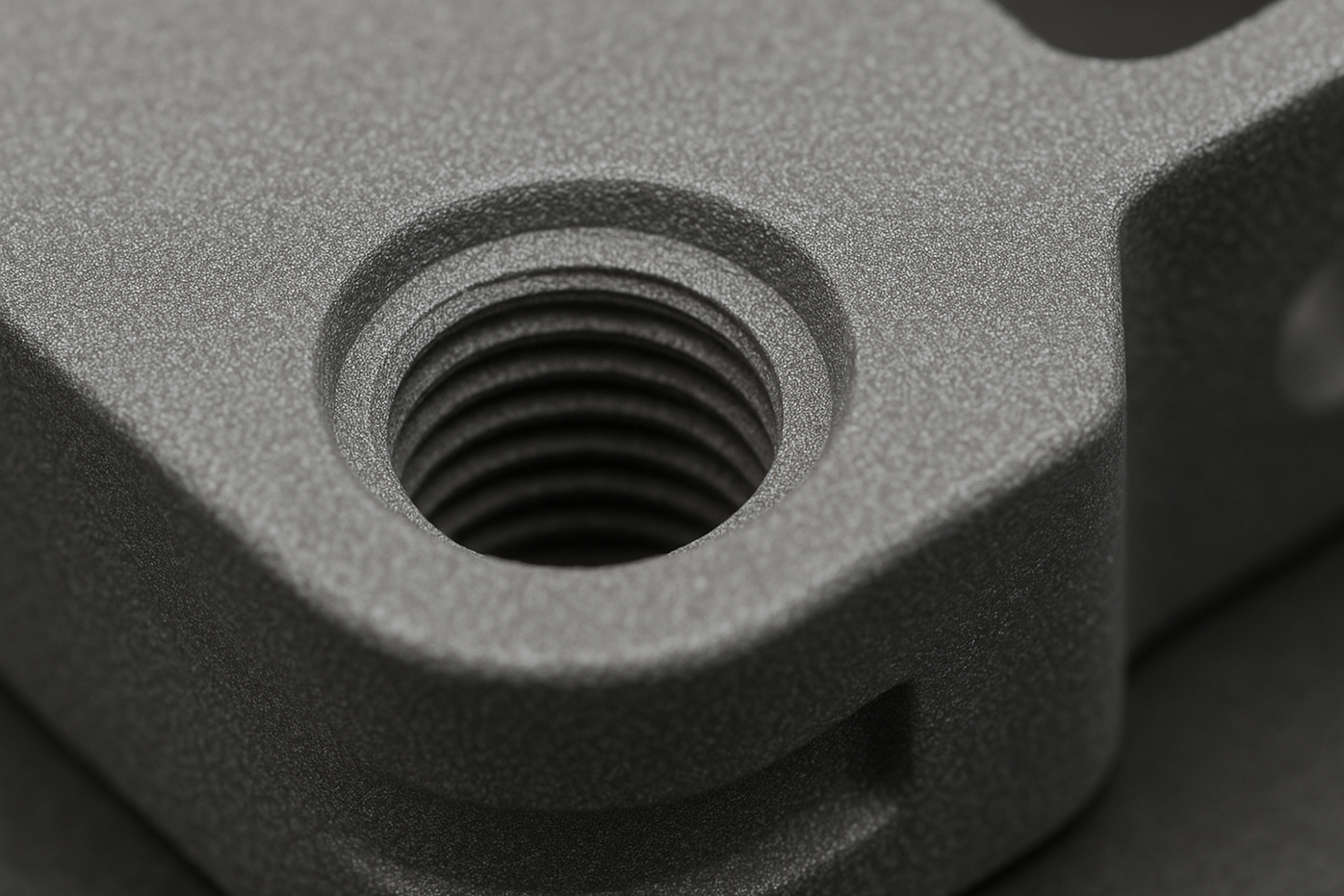

Machining: Post-process CNC machining allows for additional features, such as tapped holes.

Design Tips for Better MJF Parts

Wall Thickness:

Maintain a minimum wall thickness of 0.8 mm for standard features. For structural elements or load-bearing sections, 1.5 mm or more is recommended to ensure strength, durability, and full feature resolution.

Geometry Considerations:

MJF does not require support structures, but overhangs exceeding 8 mm may lead to slight warping or reduced edge definition. To minimize this, apply chamfers or fillets to exposed transitions and avoid sharp, unsupported edges.

Part Consolidation:

Where possible, merge assemblies into a single printed part to reduce post-processing, eliminate fasteners, and streamline manufacturing. MJF excels at producing complex geometries with internal features and moving joints.

Uniformity:

Design with consistent wall thickness and smooth transitions to reduce internal stresses and improve print quality. Avoid abrupt changes in cross-section, and use rounded corners instead of sharp angles to enhance strength and reduce warping.

Post-Processing Considerations:

Account for how secondary processes such as dyeing, vapor smoothing, or CNC machining will affect your part. These steps can alter surface finish, dimensions, and tolerances. Leave additional material where post-machining is required and anticipate slight dimensional changes from finishing techniques.

Tolerances & Fit

MJF offers typical tolerances of ±0.3 mm or ±0.3%, suitable for most functional parts. For precision fits (e.g., holes, snaps, or live hinges), design in 0.2–0.5 mm of clearance.

Common Challenges and Hidden Costs of MJF

While MJF delivers high-quality, production-ready parts, achieving those results consistently involves more complexity than many teams anticipate.

Thermal Warping & Dimensional Inconsistency

Improper nesting or orientation can lead to uneven heat distribution, causing parts to warp or lose dimensional accuracy, especially on flat or asymmetrical designs. Without careful planning, failed prints or subtle defects can occur.

Post-Processing Complexity

Raw MJF parts typically require additional finishing such as smoothing, sealing, dyeing, or precision machining to meet visual or functional standards. Each step introduces more labor, time, and potential variability in part quality.

Material Selection Nuance

Choosing between PA11 and PA12 affects performance and compliance. PA12 is stiffer and suitable for general-purpose use, while PA11 offers better ductility and impact resistance. Selecting the right material depends on application-specific needs, and the wrong choice can lead to rework or underperforming parts.

Cost Surprises from Inefficient Builds

Quoting MJF parts isn’t just about geometry. It involves packing efficiency, powder refresh ratios, part orientation, and machine utilization. Misjudging these factors often leads to unexpected cost overruns or delays.

Significant Setup Requirements

Beyond the printer itself, a reliable MJF workflow demands multiple supporting systems: a powder handling station, cleaning unit, material refresh tools, and post-processing equipment. These systems are large, costly, and require trained operators to use safely and effectively. The need for specialized infrastructure, skilled labor, and continuous upkeep makes it a significant investment that only makes sense at a certain scale of usage.

Space, Safety, and Operational Overhead

MJF systems require dedicated space with environmental controls, dust management, proper ventilation, and strict safety protocols. Routine maintenance, calibration, and staff training all add to the ongoing investment needed to keep production consistent.

Why Engineers Trust Simple Machining for MJF

With Simple Machining, you're not navigating those challenges alone. Our experts help you evaluate designs, optimize for printability, and choose the best material for your application. Most parts start at just $30, meaning there’s no steep upfront investment.

Outsourcing your MJF needs also eliminates the capital investment required for in-house systems. For reference, the cost of HP's industrial MJF printer setups often exceeds $300,000.

Need design help or fast prototypes? Use our CAD design service or on-demand 3D printing for SLA, FDM, SLS, and MJF.

How MJF Fits Into On-Demand Manufacturing

MJF additive manufacturing as a core method supports rapid iteration and short-run production without tooling delays. When paired with processes like CNC machining or urethane casting, it forms a robust on-demand manufacturing workflow.

This flexibility is especially valuable for hardware startups, medical device developers, and engineers building configurable product lines. It enables faster testing, responsive inventory management, and smoother scale-up.

Looking Ahead: The Future of MJF and 3D Printing

HP Multi-Jet Fusion printers are at the forefront of scalable additive manufacturing. As demand for personalized products and agile production grows, MJF is poised to play a central role in bridging prototyping and production.

According to MarketsandMarkets, the 3D printing industry is projected to grow from $16.6 billion in 2023 to $25.5 billion by 2030, driven by constant innovations and adoption in the automotive, medical, and consumer goods sectors.

Common Questions About MJF

What is the difference between MJF and SLS?

MJF uses fusing agents and infrared energy, while SLS relies on a laser. MJF generally builds faster and offers smoother finishes.

What is MJF 3D printing and how does it work?

MJF 3D printing is a powder bed fusion process developed by HP. It uses fusing and detailing agents combined with infrared heat to create durable, detailed nylon parts in layers.

Can MJF parts be used as end-use components?

Yes. MJF parts are strong, durable, and suitable for enclosures, mounts, and even wearable tech components.

What is the surface finish of MJF parts like?

Parts have a matte, slightly grainy finish that can be improved with post-processing.

How much does an MJF part cost per piece?

Simple Machining offers MJF parts starting at $30 before volume discounts, significantly lower than typical injection mold tooling costs.

Want instant quotes for other services, visit our homepage

Key Takeaways

- MJF delivers production-grade polymer parts with strong isotropic properties.

- MJF is well-suited for short production runs (around 50 – 500 units), functional prototyping, and digital spare parts.

- MJF outperforms FDM and SLA for functional strength and production readiness.

- MJF enables part consolidation and faster iteration without tooling costs.

- Simple Machining provides MJF printing starting at $30 before discounts.

Looking for more insights?

Sign up for the newsletter:

Designing Threads for SLS PA12: Pitch, Engagement, Reliefs, and Finishing

Read the Article 6 minute read

6 minute read

November 3rd

November 3rd

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th