- Home

- About Us

-

Industries

-

Resources

- Contact Us

Your Guide to SLS: Advantages, Materials, and Best Practices for Product Teams

Published on: July 07, 2025

By: The Simple Machining Team

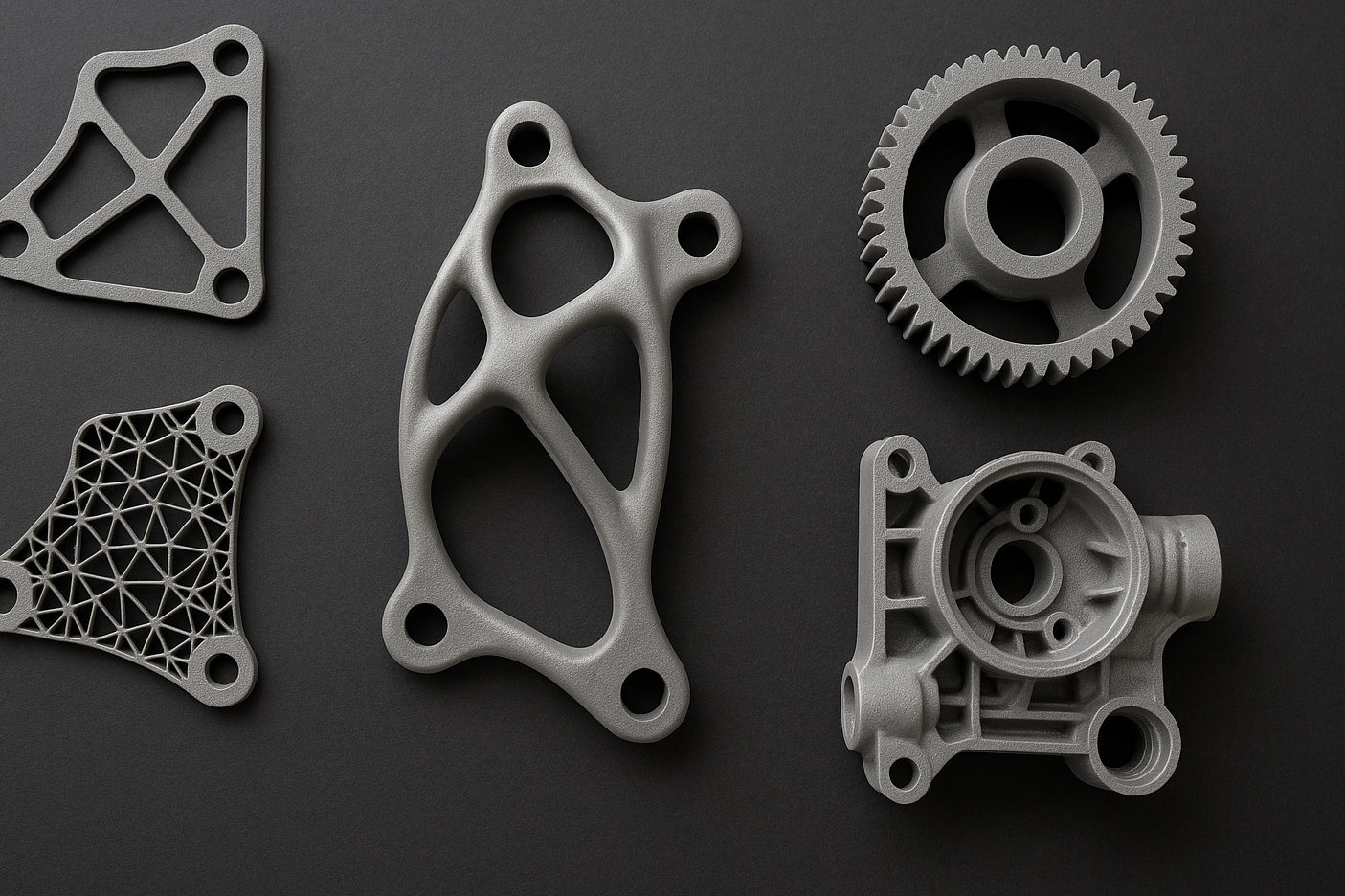

Selective Laser Sintering (SLS) is transforming how engineers and product teams approach complex, functional parts, from robust prototypes to production-quality components. Using a self-supporting powder-bed process, SLS offers unmatched design freedom, consistent mechanical properties, and scalable production capabilities without the constraints of traditional support structures.

For teams looking to accelerate design iterations and reduce production risk, SLS can be a powerful tool to bring high-performance parts to market faster. At Simple Machining, we support customers throughout the process with guidance, quality control, and flexible on-demand manufacturing services.

Further Reading:

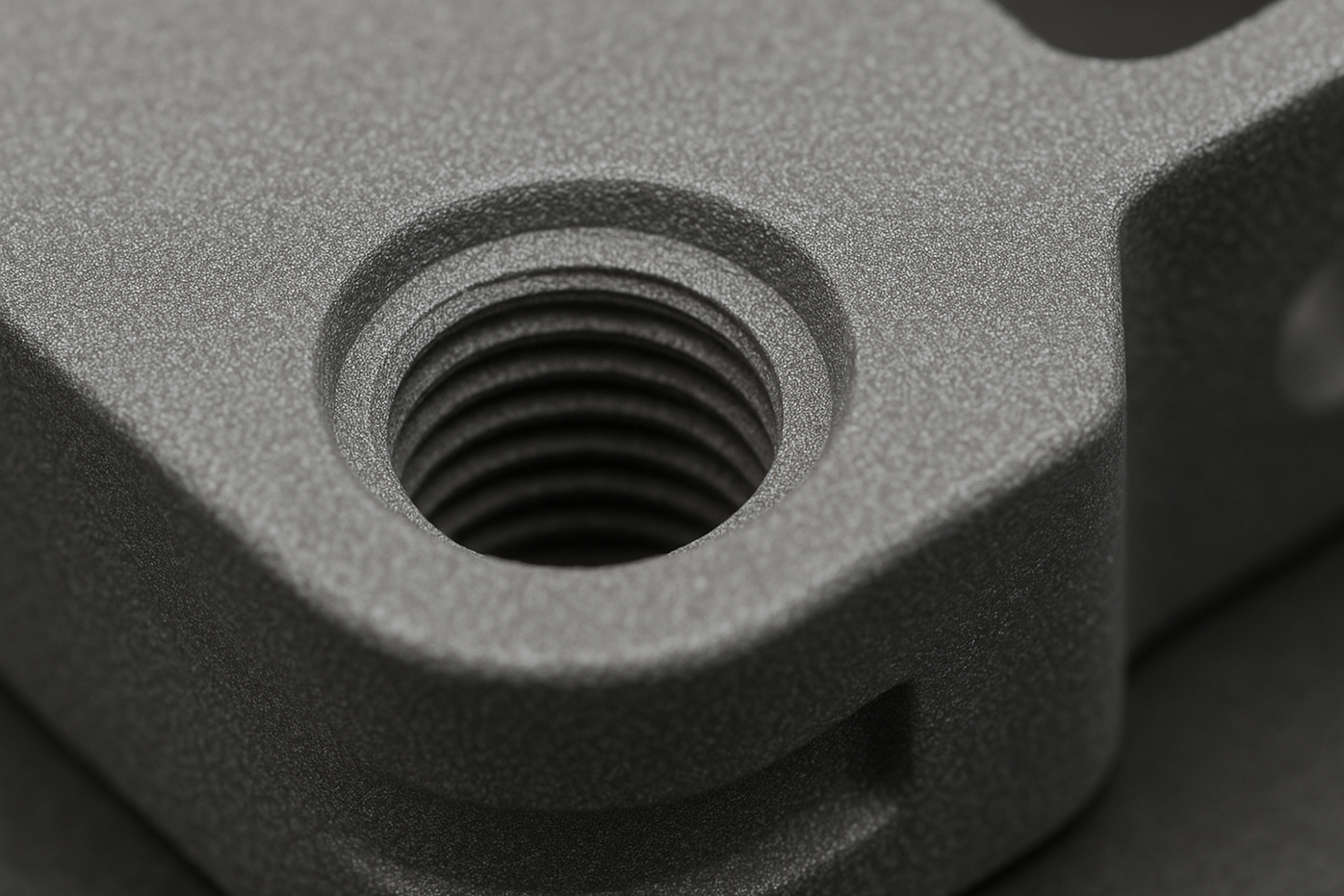

Designing Threads for SLS PA12: Pitch, Engagement, Reliefs, and Finishing

In This Article, You Will Learn:

- What SLS 3D printing is and how it works

- The sustainability and material options available for SLS

- Key advantages of SLS compared to other 3D printing methods

- Industry applications, design guidelines, and common pitfalls

- Cost factors and future trends shaping SLS technology

What Is SLS 3D Printing?

SLS is an additive manufacturing process that uses a high-power laser to fuse thermoplastic powder into solid parts. Unlike other 3D printing methods, it doesn’t require support structures, enabling complex internal geometries like lattice structures, undercuts, and integrated assemblies. The technology was first conceptualized in the 1980s by Dr. Carl Deckard and Professor Joe Beaman at the University of Texas at Austin under a DARPA research grant. The first commercial SLS printer, the SinterStation 2000, was introduced by DTM Corporation, which was later acquired by 3D Systems in 1992.

How Does SLS Work?

SLS begins with a thin layer of polymer powder (typically 0.1–0.15 mm thick) spread evenly across a heated build platform by a sweeper. A CO₂ laser selectively fuses powder particles along cross-sections defined by the CAD model. After each layer is sintered, the platform lowers, and a new layer of powder is applied. The remaining unsintered powder that surrounds the part provides natural support for overhangs and complex geometries, eliminating the need for support structures that would be discarded later.

Sustainability & Budget-Friendliness of SLS

Selective Laser Sintering (SLS) offers significant sustainability advantages over other manufacturing methods. By using a powder bed to support parts during printing, it generates minimal waste, as unsintered powder can be reclaimed and reused. Most SLS systems maintain part quality while recycling about 85% of previously used powder in a future print. This reduces overall waste and raw material consumption. Additionally, SLS enables the creation of lightweight, optimized designs that use less material, promoting more efficient and sustainable product development.

Beyond powder recycling, SLS supports on-demand production without the need for costly tooling. This helps reduce overproduction, minimize warehousing, and limit waste from unsold or obsolete parts, as you only need to produce the exact amount necessary.

Material sourcing further contributes to sustainability. Common SLS powders, such as nylon (PA12) and biocompatible PA11, are widely available from suppliers committed to responsible sourcing. Emerging plant-based feedstocks are also helping reduce dependence on fossil fuels.

At the end of their life cycle, many SLS parts made from polyamide can be mechanically recycled, offering an additional step toward a circular manufacturing model.

Unique Materials for SLS: Nylons, Composites, and Advanced Polymers

Selective Laser Sintering offers a unique value proposition in that it supports a wide range of engineering-grade materials, making it highly adaptable to different performance and regulatory needs. From durable nylons to advanced fiber-reinforced composites, SLS materials enable designers and engineers to achieve high-strength, functional parts that meet demanding mechanical, thermal, and chemical requirements.

Below are some of the most common options and their typical use cases:

Nylon 12 (PA12): A versatile, all-purpose material with balanced strength, impact resistance, and thermal stability up to approximately 175 °C.

Nylon 11 (PA11): More ductile and chemically resistant than PA12 at a shore hardness of 77D, making it ideal for snap fits, living hinges, and components exposed to harsh environments.

Fiber-reinforced nylons: Composites filled with carbon fiber or glass for improved stiffness, dimensional stability, and strength-to-weight performance. Common composites include Nylon 12-Glass-filled, Nylon 12-Carbon-Filled, and Nylon 12-Aluminum-Filled.

Biocompatible nylons: Suitable for limited-contact medical applications such as custom orthotics or surgical tools.

Specialty blends: Designed for specific requirements like ESD safety or flame retardance in electronics, automotive, and industrial parts.

Choosing the right material depends on factors like mechanical load requirements, environmental conditions, and any applicable regulatory standards. If you need help selecting the right material for your project, contact us.

Advantages of Selective Laser Sintering (SLS)

Selective Laser Sintering offers a powerful combination of design flexibility, production efficiency, and material performance that sets it apart from other 3D printing methods, giving engineers the freedom to develop functional, production-ready parts without compromise.

Support-free complexity

Enables the creation of intricate internal geometry, such as curved channels and enclosed voids, without the need for removable supports.

Strong, functional parts

Produces robust components suitable for functional prototypes and, in many cases, production-grade end-use parts.

Efficient powder reuse

Unused powder can be reclaimed and refreshed for future builds, reducing overall material waste and improving sustainability.

Scalability

Handles consistent production runs ranging from one-off prototypes to low- and mid-volume batches, offering flexibility as product lines grow.

Design freedom

Eliminates the need to redesign parts around support removal, allowing engineers to focus on performance-driven geometries rather than manufacturing constraints.

Considering SLS for your next project? Connect with our team to review your design and explore the best path forward.

SLS vs. Other 3D Printing Methods

SLS vs. FDM

Selective Laser Sintering (SLS) produces stronger, more functional parts with greater dimensional accuracy and design freedom due to its powdered thermoplastic, support-free process. In contrast, Fused Deposition Modeling (FDM) is more cost-effective for basic prototypes but has weaker layer adhesion, limited geometry options, and rougher surface finishes.

SLS vs. SLA

SLS excels at producing durable, production-grade parts with complex internal features and no need for support removal, making it ideal for functional use. Stereolithography (SLA) offers ultra-smooth surfaces and high detail, making it ideal for visual models, but lacks the mechanical strength and thermal resistance required for most real-world applications.

SLS vs. MJF

Both Selective Laser Sintering and Multi-Jet Fusion (MJF) deliver strong, support-free parts with good detail and mechanical performance. SLS offers greater material flexibility and is widely adopted in aerospace and automotive. MJF provides faster print speeds, slightly smoother finishes, and better efficiency for medium to high-volume production.

Read the full comparison guide here with our recommendations!

Industry Applications of SLS

Aerospace: Lightweight brackets, ducts, housings

SLS is ideal for producing lightweight components with optimized geometries that maintain structural strength. Engineers can design parts with variable wall thicknesses and internal structures to reduce mass without sacrificing performance. This capability is especially valuable in aerospace, robotics, and machinery, where even small weight reductions can significantly impact efficiency and cost.

Automotive: Custom air intakes, functional prototypes, fixtures

Automotive engineers rely on SLS to quickly develop durable prototypes such as air intake systems, fit test components, and precision assembly fixtures. The technology’s high thermal and mechanical performance supports realistic functional testing under demanding conditions like vibration, airflow, and heat cycling. SLS also helps reduce development time by enabling rapid design changes without retooling.

Healthcare: Custom prosthetics, surgical guides

SLS enables manufacturing patient-specific prosthetics and surgical tools tailored to unique anatomical needs at a reasonable cost. With biocompatible nylons for limited-contact applications, the process yields accurate, comfortable parts that facilitate faster recovery and enhanced clinical outcomes.

Consumer products: Rapid functional testing, wearable components

SLS helps consumer product developers quickly test functional designs using materials with near-production mechanical properties. The process also offers smooth surface finishes ideal for wearables where comfort and appearance are essential. Rapid iteration improves performance and ergonomics before full-scale production. For smaller teams, SLS is often carried through to small and medium production runs, enabling real-world testing with the final production process.

Industrial: Jigs, fixtures, and short-run end-use parts

SLS is widely used to produce custom jigs, fixtures, and production aids with high precision and repeatable strength. It enables quick turnaround and on-demand tooling for evolving production lines. Additionally, it supports cost-effective short-run manufacturing of end-use parts without the need for molds or CNC setups. When components fail, SLS allows for the rapid production of replacement parts, minimizing downtime and keeping operations on schedule.

Design Guidelines for SLS Projects and Pitfalls to Avoid

These are general guidelines to get started and ensure that your parts are printable.

General Tolerance:

- Account for ±0.05 mm (0.002”) typical accuracy.

Orientation

- Design parts with a clear print orientation in mind.

- While support structures aren’t needed in SLS, thoughtful orientation reduces warping and helps maintain surface quality on key features.

Minimum Feature Size

- >0.75 mm (≈0.03”)

- Smaller features may be lost or collapse during printing. For fine details, consider increasing wall thickness locally.

Wall Thickness

- Minimum: ≥1 mm (≈0.04”)

- Recommended for rigid parts: ≥3 mm (≈0.12”)

- Thicker walls reduce the risk of warping and improve overall part strength.

Powder Removal

- Include drainage holes in hollow parts.

- Fully enclosed volumes without escape paths will be printed as solid, which increases print time, weight, and material costs.

Post-Processing Options for SLS

- Dyeing: Uniform coloration for aesthetics or branding

- Vapor smoothing: Improves surface finish, seals porosity, enhances moisture resistance

- Nickel Plating: Makes the part stiffer and more wear-resistant. Leaves a rough surface finish.

How Much Does SLS 3D Printing Cost?

The cost of SLS 3D printing varies based on part geometry, material selection, print volume, and required finishing processes. Because SLS requires specialized equipment and powder handling, it is generally more expensive than FDM; however, it offers higher performance and design freedom, making it a cost-effective choice for functional prototypes and small-batch production.

The Future of SLS

The Selective Laser Sintering (SLS) market is rapidly expanding, fueled by ongoing advances in composite materials, faster sintering technologies, and growing demand in end-use applications. In 2023, the global SLS printer market was valued at approximately USD 1.35 billion and is projected to reach around USD 2.8 billion by 2032, reflecting a compound annual growth rate (CAGR) of 8.5%.

Innovations in material science, including fiber-reinforced composites, flexible polymers, and ESD-safe powders, are driving broader adoption across aerospace, automotive, healthcare, and electronics industries.

Why Choose Simple Machining for SLS

Our team provides:

- Expert guidance on material and design selection

- Fast, reliable on-demand manufacturing

- Quality assurance for functional parts

- Support from design, prototype, and production

- 15+ years of additive experience in-house

Frequently Asked Questions

Can SLS be used for production?

Yes, it’s well-suited for low- to mid-volume production of functional parts.

Are SLS parts weather-resistant?

Nylon 12 parts are generally UV- and moisture-resistant for outdoor use.

How much does it cost to 3D print in SLS?

While SLS is generally more expensive than FDM, it offers unique, high-performance materials. At low to medium volume, SLS can become more cost-effective than FDM.

Key Takeaways

- Functional and Production-Ready: SLS creates strong, reliable prototypes and end-use parts.

- Support-Free Complexity: The powder bed enables intricate geometries without support structures.

- Versatile Materials: Offers a wide selection of nylons and composites for demanding applications.

- Consistent Repeatability: Ensures stable mechanical and dimensional properties across builds.

- Sustainable: Promotes powder reuse and on-demand production to reduce waste and cost.

Discover how our on-demand SLS services can streamline your product development. Request a quote today.

Looking for more insights?

Sign up for the newsletter:

Designing Threads for SLS PA12: Pitch, Engagement, Reliefs, and Finishing

Read the Article 6 minute read

6 minute read

November 3rd

November 3rd

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th