- Home

- About Us

-

Industries

-

Resources

- Contact Us

How Overlooking Tolerances Can Sink Your Machining Project

Published on: August 04, 2025

By: The Simple Machining Team

Too many engineers treat tolerances like a footnote during early design, only to pay for it later in delays, cost overruns, and unusable parts.

[Blog Coming Soon: How to correctly tolerance your design]

What Are Machining Tolerances and Why Do They Matter?

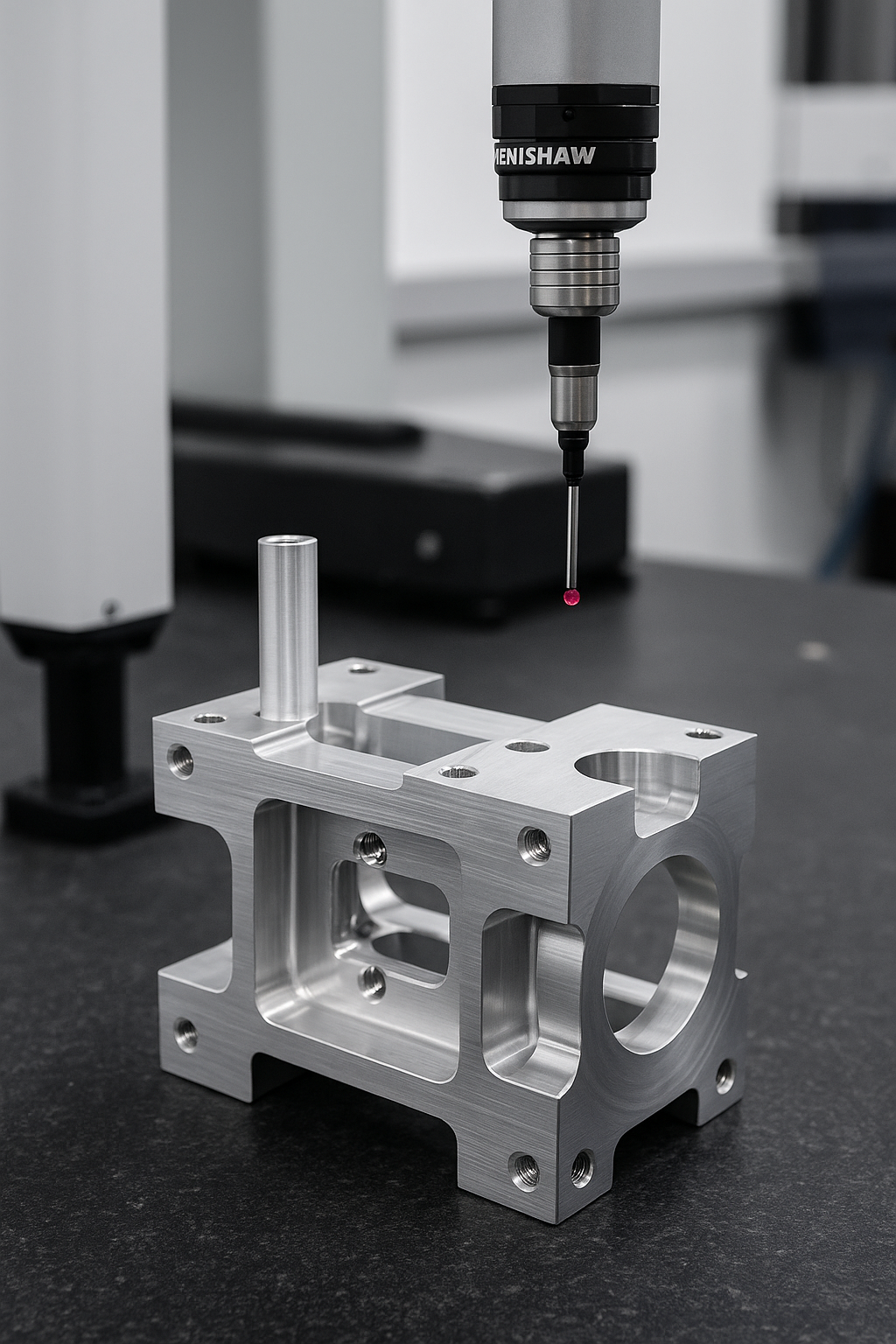

Tolerance in manufacturing refers to how much a part's actual dimensions can vary from its nominal specs. These variations can affect every stage of production, from quoting to machining strategy.

Even simple parts are impacted by tolerancing decisions. They influence material usage, fixture design, machining time, and rework risk. When tolerances are inconsistent or unclear, it often leads to delayed quotes, unexpected costs, or rejected parts.

Tight tolerances drive up cost by requiring slower toolpaths, specialized tools, and more inspection. Loose tolerances reduce cost but may compromise function. The goal is to strike the right balance between performance and manufacturability.

Common Tolerance Mistakes in Early Design

Here are the biggest pitfalls we see:

Over-tolerancing

Applying tight tolerances to non-critical features increases cost and slows production. If a dimension isn’t functionally important, there’s no need to tolerance it tightly.

Relying on CAD Defaults

Many CAD programs assign default tolerances that don’t reflect real-world machining capabilities. If left unreviewed, these default settings can lead to quoting issues or unexpected tooling requirements. Always verify and adjust tolerances based on the actual function and manufacturability of the part.

Ignoring Tooling Limits

Designing deep holes, tight internal radii, or complex geometries without considering tooling constraints can require extra setups or custom tools. These features add cost, complexity, and time.

How Early Tolerance Planning Helps

Thinking about tolerances early leads to better outcomes:

Faster quotes: Clear, reasonable tolerances help shops quote your part without questions or rework.

Lower cost: Standard tolerances use standard tools and reduce inspection steps.

Fewer delays: You avoid surprises that force you to go back and revise drawings.

[Blog Coming Soon: How to correctly tolerance your design]

Collaborating With Machining Partners on Tolerances

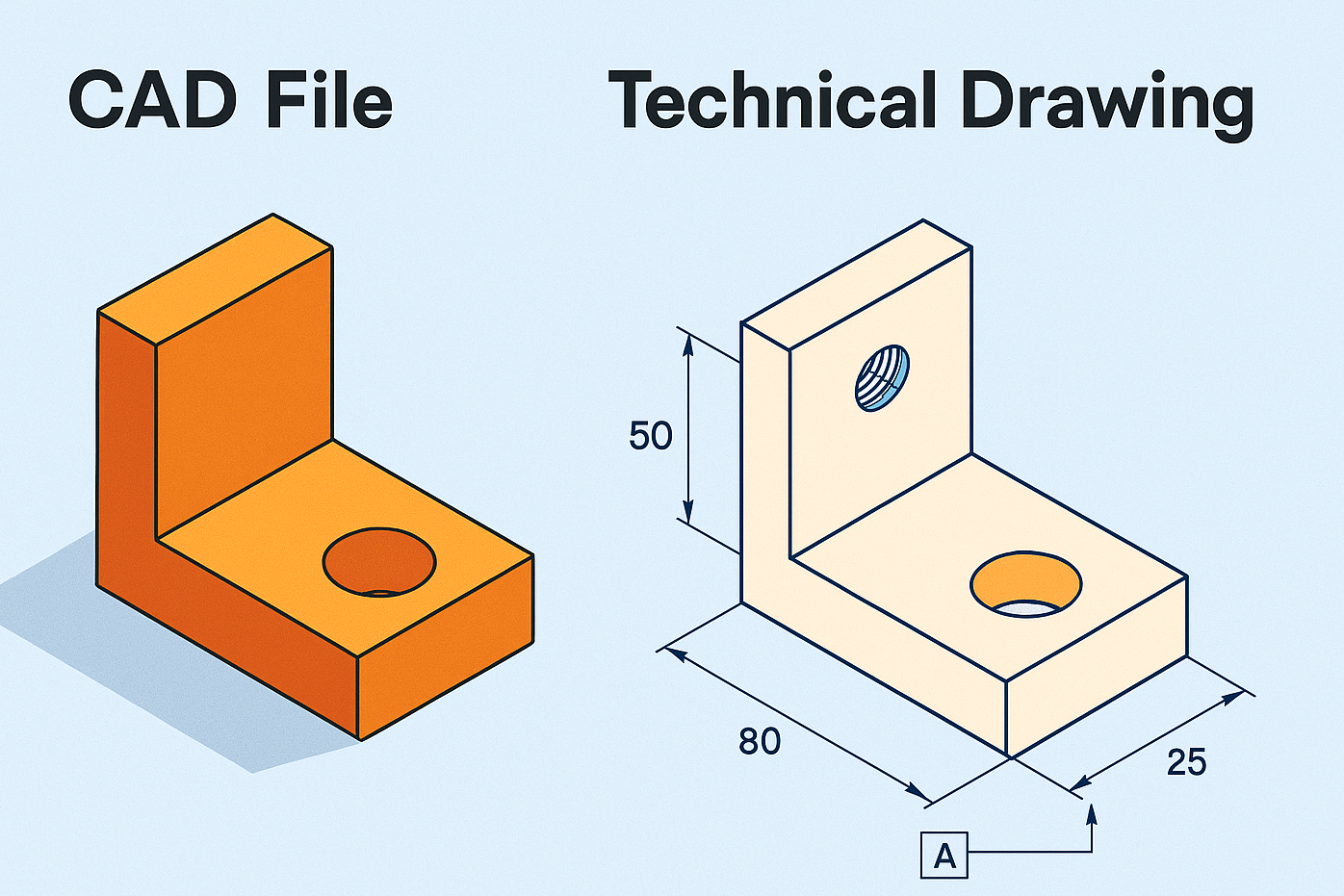

If you’re sourcing machined parts from an external supplier, especially in low volumes, make it easy for them to help you. We recommend including 2D drawings alongside your 3D models, especially when critical tolerances are involved. Drawings provide context that 3D files alone often lack, assisting manufacturers to assess feasibility.

Be sure to call out functional features explicitly. These aren’t always obvious from the geometry, and clear labeling helps prevent misinterpretations. If you're unsure whether your tolerances are realistic or practical to machine, ask for feedback during the quoting process.

At Simple Machining, every CAD design project includes a standard reference drawing to support this exact need. Learn more about our CAD services.

Final Thoughts: Precision Starts with Planning

Just having a tolerance spec for the sake of having it isn't enough; they directly impact cost, lead time, and whether your part gets manufactured correctly the first time. It is critical to be intentional with tolerancing in the design stage. Overly tight or unclear tolerances can lead to unnecessary revisions, quoting delays, or outright rejections. In contrast, well-thought-out tolerances that align with real functional needs help streamline production and improve part performance.

By planning tolerances early, engineers reduce back-and-forth during RFQs and lay the groundwork for faster, more predictable outcomes.

Learn more about Simple Machining’s full scope of services from ideation to production.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

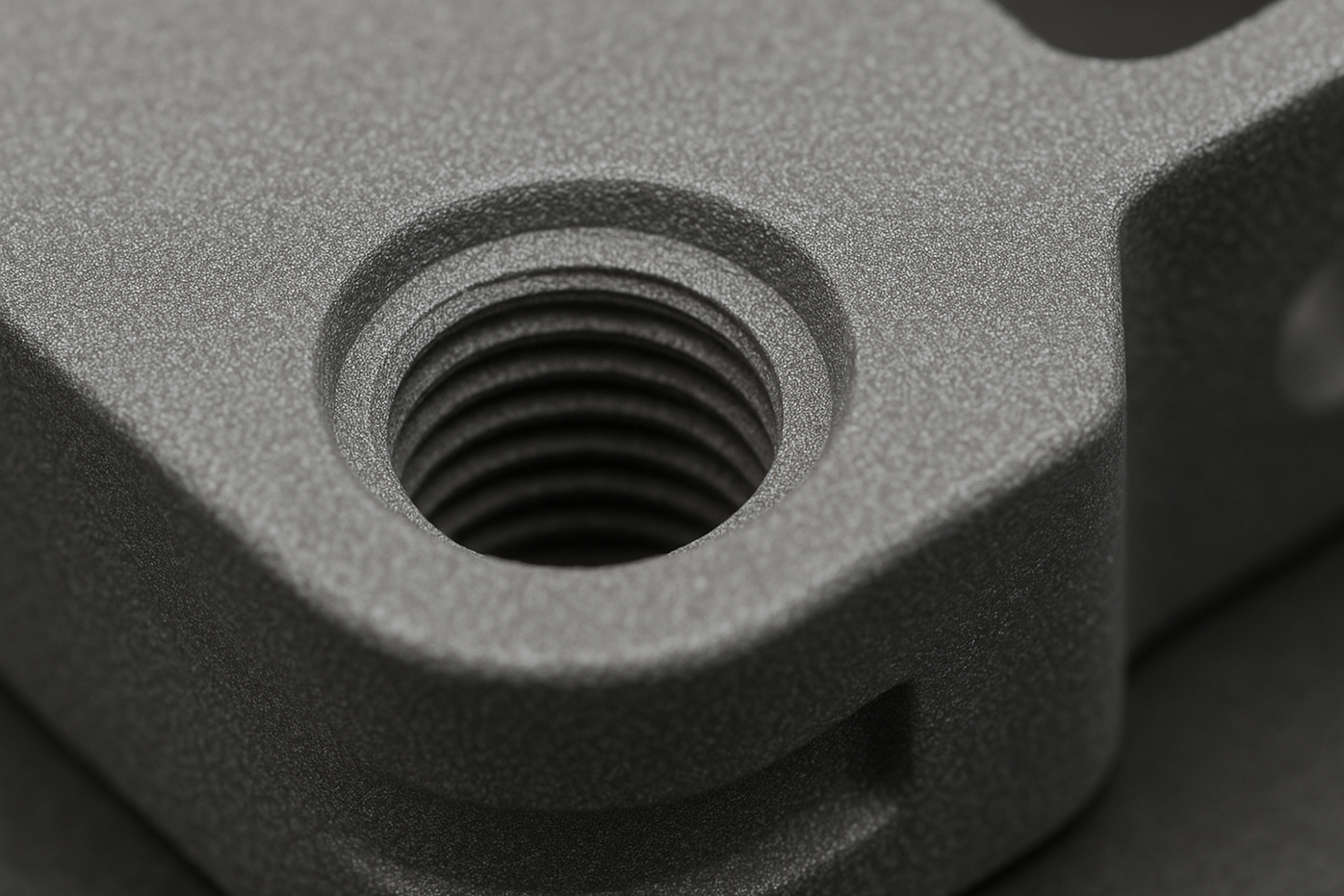

Designing Threads for SLS PA12: Pitch, Engagement, Reliefs, and Finishing

Read the Article 6 minute read

6 minute read

November 3rd

November 3rd

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th