- Home

- About Us

-

Industries

-

Resources

- Contact Us

What Project Managers Need to Know About 3D Printer Resolution

Published on: August 20, 2025

By: The Simple Machining Team

For engineers and product developers, resolution is often presented as a headline metric of print quality. In practice, however, its significance depends on the printing technology and the application at hand. The key consideration is not resolution in isolation, but how it affects surface finish, feature fidelity, and part performance in real-world conditions.

In this Article

This article explains how resolution affects visual quality, dimensional fidelity, and functional strength. It also highlights the limits of resolution as a standalone metric and offers practical context for comparing machine settings or selecting the right 3D printing process during prototyping and low-volume production.

What Is 3D Printer Resolution and Why Does It Matter?

In additive manufacturing, "resolution" refers to how finely a printer can reproduce details within a part. It is usually described in two parameters:

- Z-resolution (layer height): The thickness of each deposited layer along the vertical axis. Smaller layer heights create smoother surfaces and better capture curves or angled geometries, but they increase print time and material use.

- XY-resolution: The smallest movement the printer can make in the horizontal plane. This is influenced by factors such as the motion system (see: corexy), belt tension, and nozzle size. Higher XY-resolution enables sharper corners, cleaner edges, and more defined embossed or engraved features.

While both Z and XY resolution influence the visual detail and surface finish of a part, resolution is not the same as accuracy. A machine can have high resolution but still produce inaccurate parts if it lacks mechanical precision or process consistency.

How Resolution Works Across Different 3D Printing Technologies

Different additive processes have distinct resolution characteristics based on their print mechanisms and material systems. Here’s a breakdown of how resolution manifests across common technologies:

FDM (Fused Deposition Modeling):

Typical layer heights range from 0.1 to 0.3 mm. FDM is ideal for larger prototypes, functional brackets, or structural components. However, surface texture can be visibly layered, especially with higher layer heights. The nozzle diameter (usually 0.4 mm) limits feature sharpness in the XY plane.

Learn more about FDM

SLA (Stereolithography):

SLA offers excellent Z and XY resolution due to its laser-curing process. Layer heights can be as low as 0.025 mm (0.00098”). This makes SLA suitable for visual prototypes, small parts with intricate geometry, or assemblies that require smooth mating surfaces.

Read our in-depth guide to SLA:

SLS (Selective Laser Sintering):

Uses a laser to fuse powder, delivering layer heights between 0.1–0.15 mm. Surfaces are slightly grainy, and small features (like holes or embossing) are less crisp than SLA. Its advantage, however, is that parts require no support structures, enabling complex geometries.

Read more about SLS:

MJF (Multi Jet Fusion):

MJF achieves comparable layer resolution to SLS but offers more uniform surface finish and sharper feature definition. It is commonly used for functional enclosures, snap fits, and housings with live features such as hinges.

Read our MJF guide:

The actual resolution you see in a part depends not only on the technology but also on machine setup, material properties, and post-processing. This is why it is essential to communicate your needs with the vendor to achieve desired results.

Understanding the Difference Between Resolution and Accuracy

Although often used interchangeably, resolution and accuracy describe different aspects of 3D printing quality:

Resolution is the minimum unit of movement a printer can produce, typically defined in microns for both Z (layer height) and XY (lateral movement).

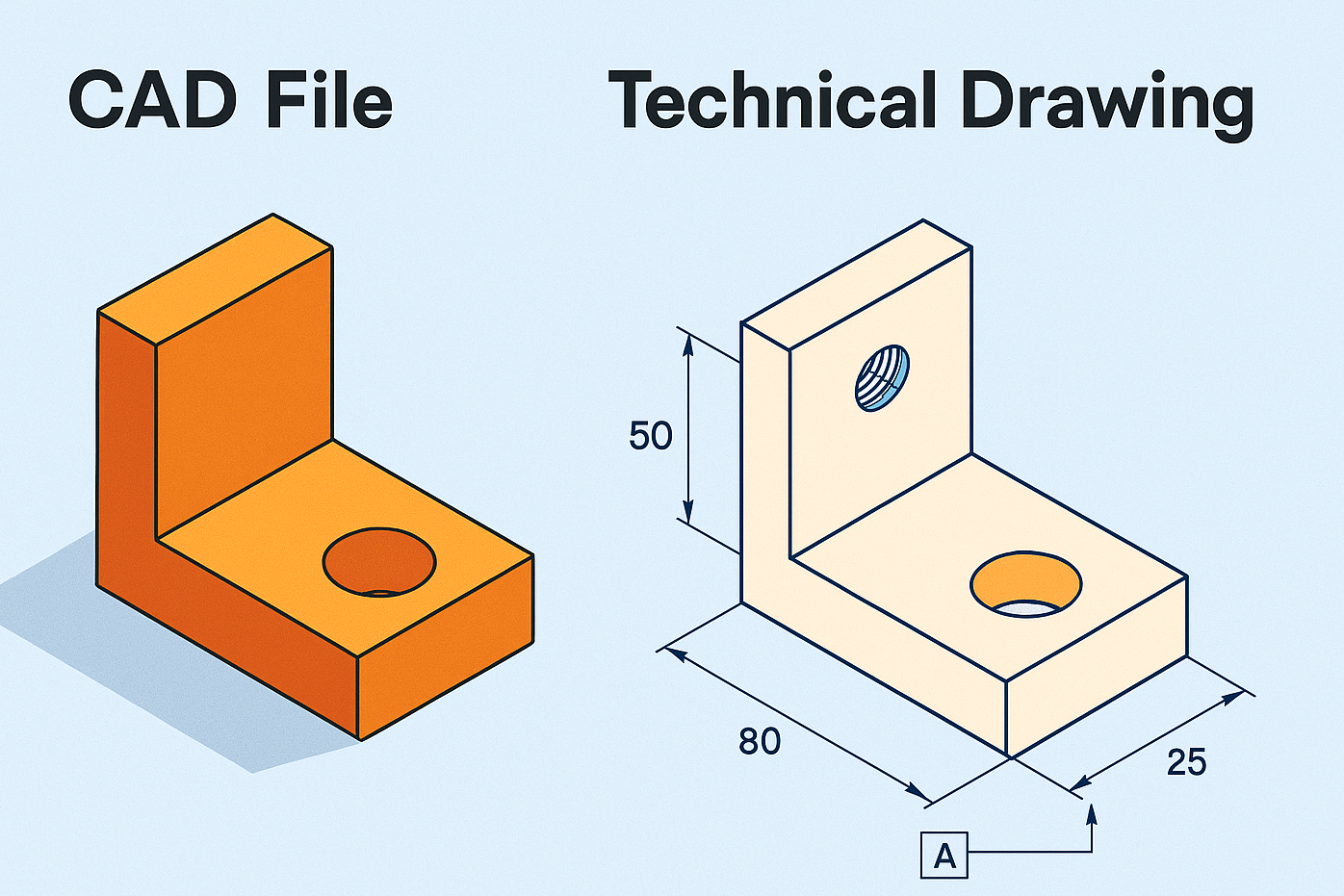

Accuracy reflects how closely the finished part matches the original CAD model.

A printer can have high resolution yet still produce inaccurate parts if mechanical or material issues interfere with the process. Common sources of inaccuracy include backlash in the motion system, resin vat warping, thermal distortion, or uneven cooling.

For applications with tight tolerance requirements, resolution should always be evaluated alongside:

- Calibration quality and process repeatability

- Documented dimensional tolerances

- Post-processing methods such as curing or surface smoothing

For example: A desktop SLA printer may advertise a Z-resolution of 25 microns and an XY-resolution of 80 microns. On paper, this suggests the ability to print highly detailed features. However, if the resin vat is slightly warped or the galvanometers aren’t calibrated properly, the part may come out with dimensional drift or inconsistent wall thickness—even though the layer lines appear smooth. This is a case of high resolution but poor accuracy due to mechanical or process variability.

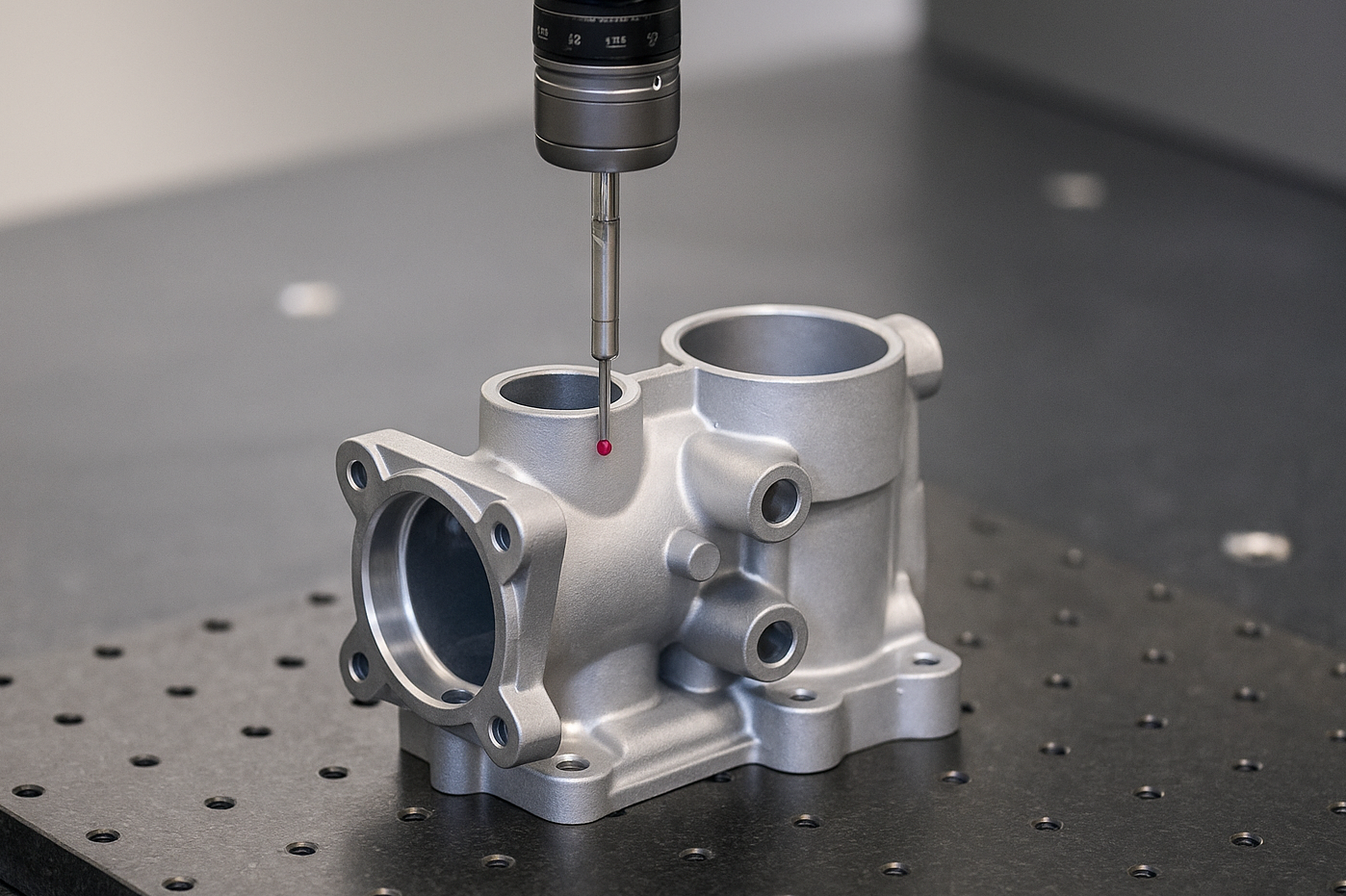

In cases where fine tolerances are critical, subtractive processes like CNC machining may offer better reliability and geometric precision. Learn more about our CNC services in various plastics, metals, and alloys.

Matching Resolution Settings to Part Objectives

Resolution should be chosen based on the balance between function, appearance, and efficiency. Here are some general guidelines:

Fine Resolution (≈0.05 mm layer height):

Best for small text, tight-fitting assemblies, or cosmetic surfaces. Improves surface quality and dimensional fidelity, but increases print time and cost.

Standard Resolution (≈0.2 mm):

A practical choice for test fits, general-purpose prototypes, and parts with moderate detail. Balances clarity with efficient build times and is widely used for early-stage designs..

Lower Resolution (≥0.3 mm):

Useful for draft concept models where speed and cost outweigh aesthetics. Produces visible stepping on curves and corners, but enables fast iteration on shape and form.

By matching resolution to application needs, development teams can avoid over-engineering and focus resources where they matter most.

Resolution as One Part of the Manufacturing Equation

Resolution plays a vital role in 3D printing, but it should not be seen as the sole measure of part quality. It is best considered in the context of surface finish expectations, function-critical features, and overall project timelines. By understanding how resolution impacts different technologies and applications, engineers can make more informed decisions during both prototyping and production.

For teams developing end-use parts or prototypes with specific visual or dimensional requirements, collaborating with an experienced additive manufacturing partner can ensure resolution settings are optimized alongside performance, cost, and reliability.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

How Overlooking Tolerances Can Sink Your Machining Project

Read the Article 4 minute read

4 minute read

August 4th

August 4th