- Home

- About Us

-

Industries

-

Resources

- Contact Us

Toxic Fumes, Microplastics, and Cancer: The Hidden Health Risks of 3D Printing

Published on: July 21, 2025

By: The Simple Machining Team

3D printing has come a long way from hobbyist kits and prototypes. As businesses and teams increasingly rely on additive manufacturing for end-use parts, it’s important to consider the safety risks involved, especially when printing indoors. Many printing methods release airborne particles, chemical fumes, or skin irritants that can accumulate over time if not properly managed. This guide breaks down the most common health concerns associated with FDM, SLA, SLS, and MJF printing, and explains how professional shops keep their environments safe.

What You’ll Learn

- Which 3D printing processes emit harmful particles or chemicals

- How common symptoms like coughing or skin irritation may relate to 3D printing

- Safety protocols professionals use and which ones you can adopt

- How to evaluate when to print in-house vs. outsource

Ultrafine Particles and Air Quality Concern

Airborne particle emissions are among the most common and under-recognized risks of 3D printing. These fumes are often too small to see but can cause respiratory issues when inhaled, especially in poorly ventilated areas.

FDM

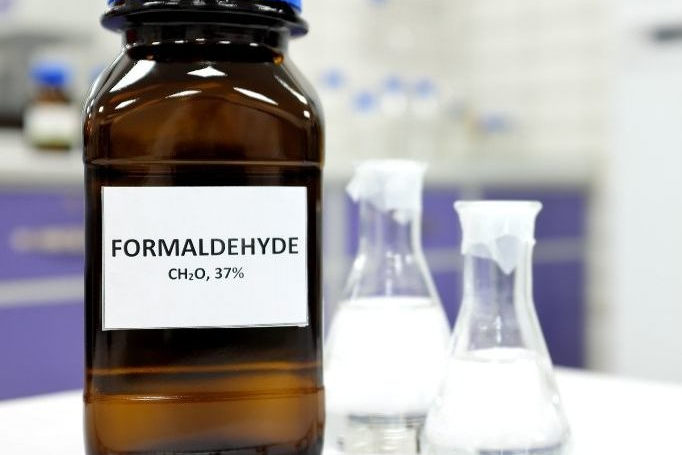

Fused Deposition Modeling (FDM) melts thermoplastic filament, such as PLA or ABS, to build parts layer by layer. As the filament is heated and extruded, the process releases fumes which are ultrafine particles (UFPs) and volatile organic compounds (VOCs), including styrene and formaldehyde. UFPs are small enough to bypass the lungs’ natural filtration, contributing to the buildup of inhalable microplastics over time. Formaldehyde, although naturally occurring, is a known irritant and potential carcinogen associated with eye irritation, respiratory issues, or potentially cancer. When exposed to high concentrations. Emissions tend to increase with higher print temperatures and specialty filaments containing additives. Even PLA, often marketed as "non-toxic," can generate significant particle levels without adequate ventilation.

SLS

Selective Laser Sintering (SLS) uses fine nylon or metal powders that become airborne when handled. These particles, especially those smaller than 2.5 microns (PM2.5), can reach deep into your lungs. A 2024 study in Multidiciplinary Science Journal found that powder-handling areas can exceed safe dust levels if not properly controlled.

Chemical Exposure and VOC Emissions

Volatile organic compounds (VOCs) released during printing can contribute to eye, skin, and respiratory irritation. Long-term exposure may carry more serious health implications.

MJF

Multi-Jet Fusion (MJF), a process invented by HP, operates at high temperatures, fusing powdered materials with infrared heat and chemical agents. Caprolactam, a known irritant, is one of the most common emissions. HP’s safety guidelines recommend engineering controls and air monitoring. Independent field tests have confirmed VOC spikes during extended runs without enclosure-based filtration.

SLA

Stereolithography (SLA) uses liquid resins cured by UV light. Many commercial resins include sensitizers that can cause skin irritation or respiratory irritation. Uncured resin is especially risky when touched or inhaled, as off-gassing can continue even after printing is complete. The risks are higher with unventilated spaces or when handling uncured resin without gloves and goggles.

Read our article on comparing FDM, SLA, SLS, and MJF with our recommendations!

Reducing Risk Through Professional Manufacturing

Industrial Ventilation & UL 2904 Compliance

Service bureaus typically operate within dedicated print rooms equipped with negative-pressure airflow, HEPA and activated carbon filtration, and real-time air monitoring. These setups align with UL 2904, the widely adopted emissions guideline for 3D printing processes that help limit both particle and chemical exposure.

Certified PPE & Powder-Handling Protocols

Professional print shops use full PPE and follow written protocols for powder handling, curing, and post-processing. From batch tracking to material safety data sheets (SDS), the controls in place go beyond what’s feasible for most users.

DIY Safety in Small Shops

While outsourcing offers the safest path, small teams can reduce their risk by upgrading workspaces and habits.

Ventilation & Filtration Essentials

Operate printers in isolated, well-ventilated rooms, not shared workspaces. Use filtration-equipped enclosures or install local exhaust systems with HEPA and activated carbon filters. Monitor air quality when running extended or multi-printer jobs.

Safe Material Handling & Waste Disposal

Always review the Safety Data Sheet (SDS) for each material before use, and wear proper personal protective equipment such as gloves and goggles when handling resins or powders. SLA parts should be fully cured before sanding to avoid releasing uncured resin dust into the air. Dispose of resin waste, used gloves, and filters in accordance with local hazardous waste guidelines. These materials should never be thrown in regular trash or poured down the drain, as they may pose environmental and health risks.

Regulations and Industry Standards

Additive manufacturing is covered under several industrial health and safety frameworks:

NIOSH, OSHA & UL 2904

The CDC’s National Institute for Occupational Safety and Health (NIOSH) has issued guidance for school and small-business 3D printer setups, emphasizing localized ventilation and PPE. OSHA requires proper chemical labeling under the Hazard Communication Standard 1910.1200. UL 2904 provides the benchmark for equipment emissions.

ISO/ASTM 52911 for Powder-Bed Fusion and Sintering

This standard outlines best practices for powder containment, operator protection, and machine safety. It’s a useful reference point when evaluating vendors who offer SLS or MJF services.

Why Let Simple Machining Handle Your FDM, SLS, MJF & SLA Projects?

At Simple Machining, we take safety seriously. Every printer we operate has its own enclosed environment with dedicated filtration and strict handling protocols, resulting in a cleaner, safer workspace.

Get started with a quote today!

FAQs About 3D Printing Safety

Is 3D printing safe indoors?

Only with proper ventilation, filtration, and safety practices.

Are resin printers toxic?

Uncured resin can cause skin and lung irritation. Proper handling and curing are key.

Can 3D printers cause respiratory problems?

Yes. Processes like FDM and SLS release ultrafine particles that can be inhaled deeply into the lungs.

What are UL 2904 standards?

UL 2904 sets guidelines for acceptable emissions levels from 3D printers and helps benchmark safety across processes.

Does 3d printing cause a smell?

Yes, 3D printing can cause a noticeable smell, especially with materials like ABS or liquid resins. These odors come from VOC emissions and may indicate poor ventilation.

Key Takeaways

- 3D printing processes such as FDM, SLS, MJF, and SLA can emit ultrafine particles and VOCs.

- Without proper ventilation or PPE, users risk respiratory and dermal exposure.

- Professional manufacturing partners mitigate these risks through the implementation of engineered controls, certified processes, and adherence to environmental safety standards.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

What Project Managers Need to Know About 3D Printer Resolution

Read the Article 6 minute read

6 minute read

August 20th

August 20th

Is MJF Right for Your Project? Everything You Need to Know

Read the Article 11 minute read

11 minute read

July 14th

July 14th