- Home

- About Us

-

Industries

-

Resources

- Contact Us

The Difference Between CAD Files and Technical Drawings

Published on: October 14, 2025

By: The Simple Machining Team

For engineers and buyers requesting machined or 3D-printed parts, one of the most common sources of quoting delays is confusion over file submissions. Specifically, whether to upload a CAD file, a technical drawing, or both.

Understanding the role each file plays in the quoting and manufacturing process can save time and prevent costly miscommunications. This post breaks down the differences between CAD files and technical drawings, why both may be required, and how to avoid common mistakes when submitting parts for on-demand manufacturing.

What Is a CAD File?

CAD (Computer-Aided Design) files are 3D models created in software like SolidWorks, Fusion 360, or Autodesk Inventor. These files define the part’s geometry-its overall shape, size, and features. Common formats include:

- STEP (.step, .stp)

- IGES (.iges, .igs)

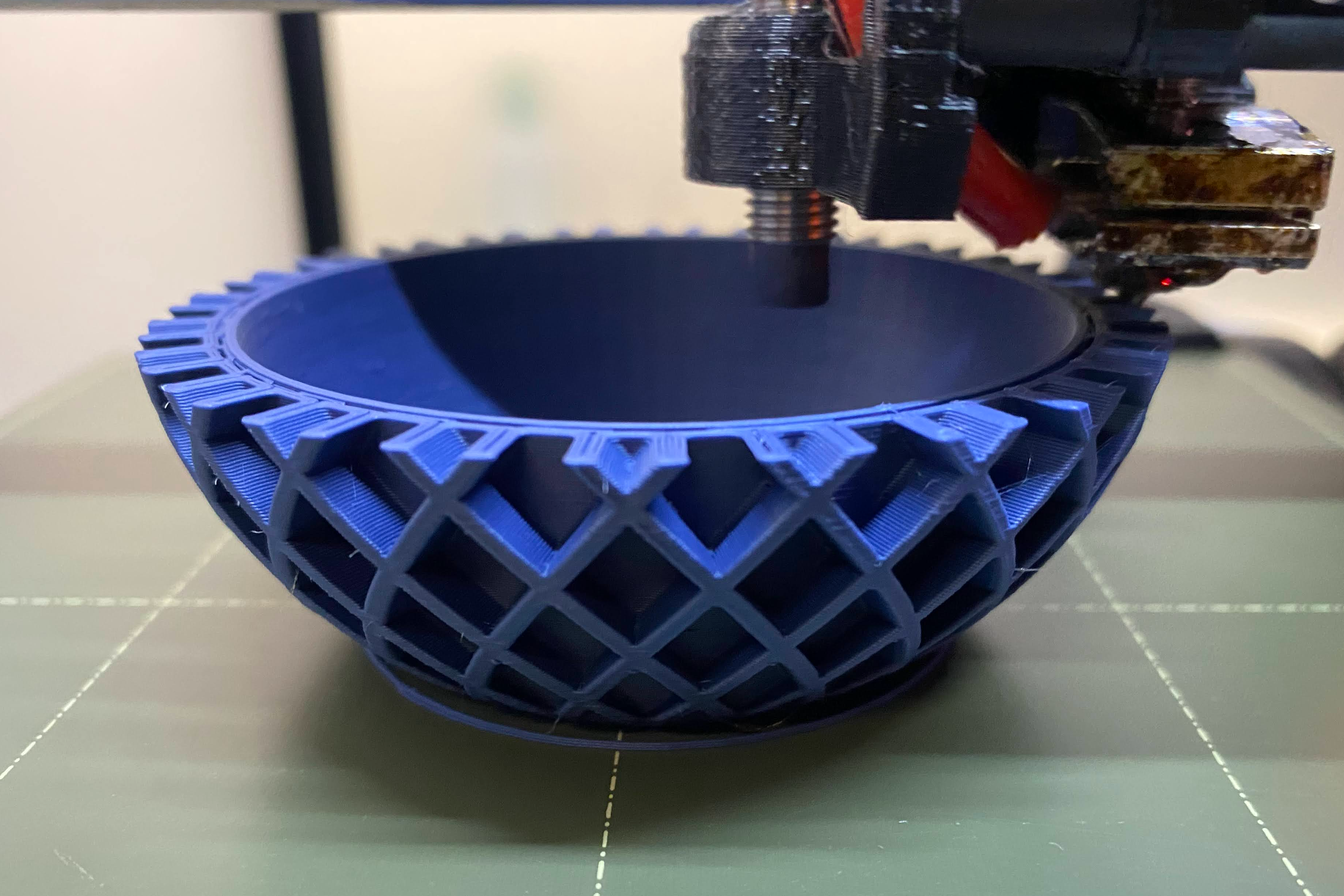

- STL (.stl)

- Native proprietary formats (.sldprt, .f3d, etc.)

CAD files are essential for communicating how a part should look in three dimensions. For additive manufacturing, they are often sufficient. For CNC machining, however, a CAD file alone doesn’t tell the whole story.

What Is a Technical Drawing?

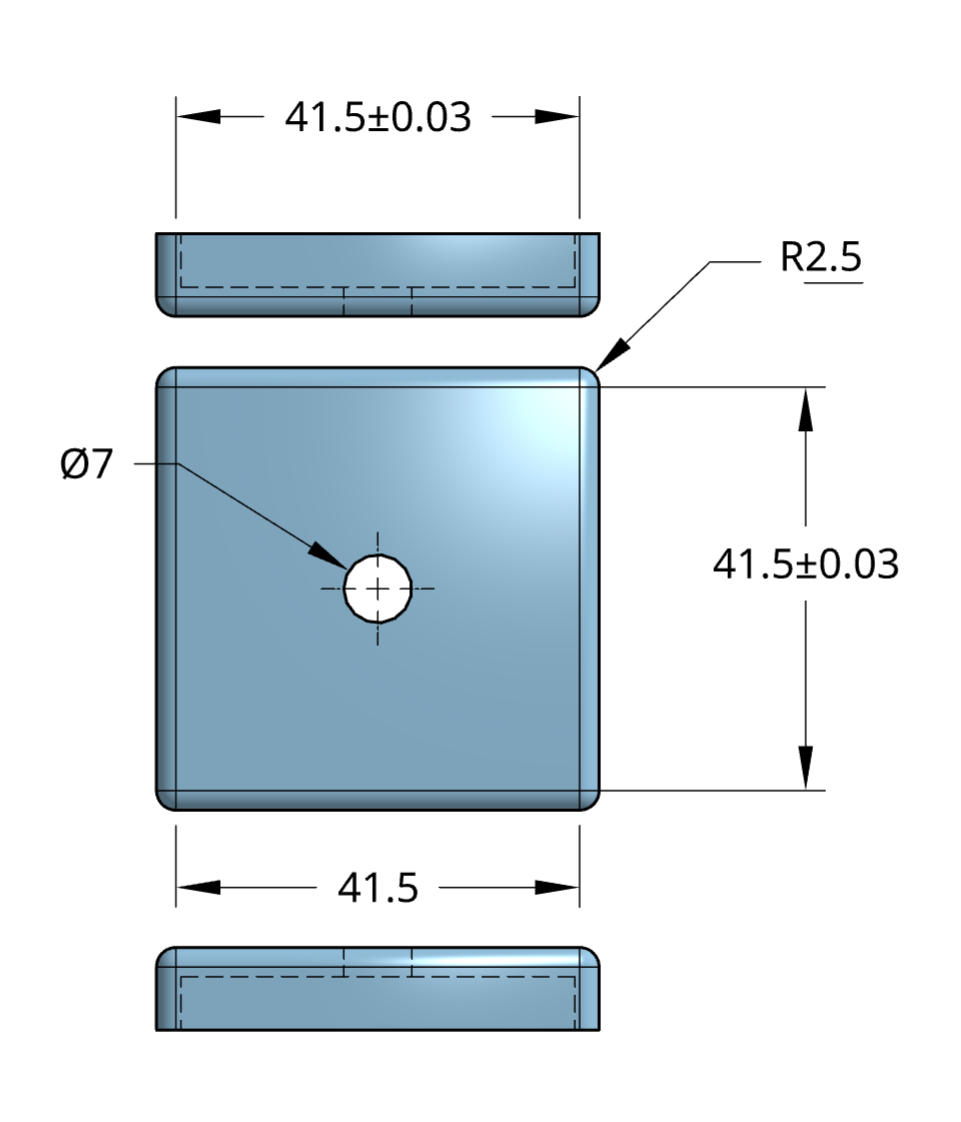

A technical drawing (or engineering drawing) is a 2D document, typically in PDF format, that defines additional specifications not always present in the CAD model. It supports manufacturing by controlling how the part should be machined and inspected.

Tolerances

Tolerances specify acceptable dimensional variation. For example, a hole specified at Ø10.00 mm ±0.05 mm means the diameter can vary from 9.95 mm to 10.05 mm. These are critical in assemblies where precise fits are required.

Surface Finishes

Surface finish requirements define roughness or smoothness using parameters like Ra (arithmetic average roughness). For instance, Ra 1.6 µm is typical for machined surfaces, while Ra 0.8 µm might be required for sealing interfaces.

Thread Callouts

Drawings identify thread types (e.g., M6 × 1.0 or ¼”-20 UNC), depth, and class of fit. This eliminates ambiguity in hole features that may appear as plain bores in CAD files.

Hole Depths

Drawings specify whether holes are through, blind, or counterbored, and include callouts for depth tolerances, avoiding misinterpretation from 3D geometry alone.

Critical Dimensions

These are dimensions that directly affect function or assembly. They are often flagged with symbols (e.g., a triangle or box) to alert machinists to their importance.

Material Notes

Drawings list required materials (e.g., 6061-T6 aluminum, 316 stainless steel), and may include specifications for hardness, grain direction, or certification needs.

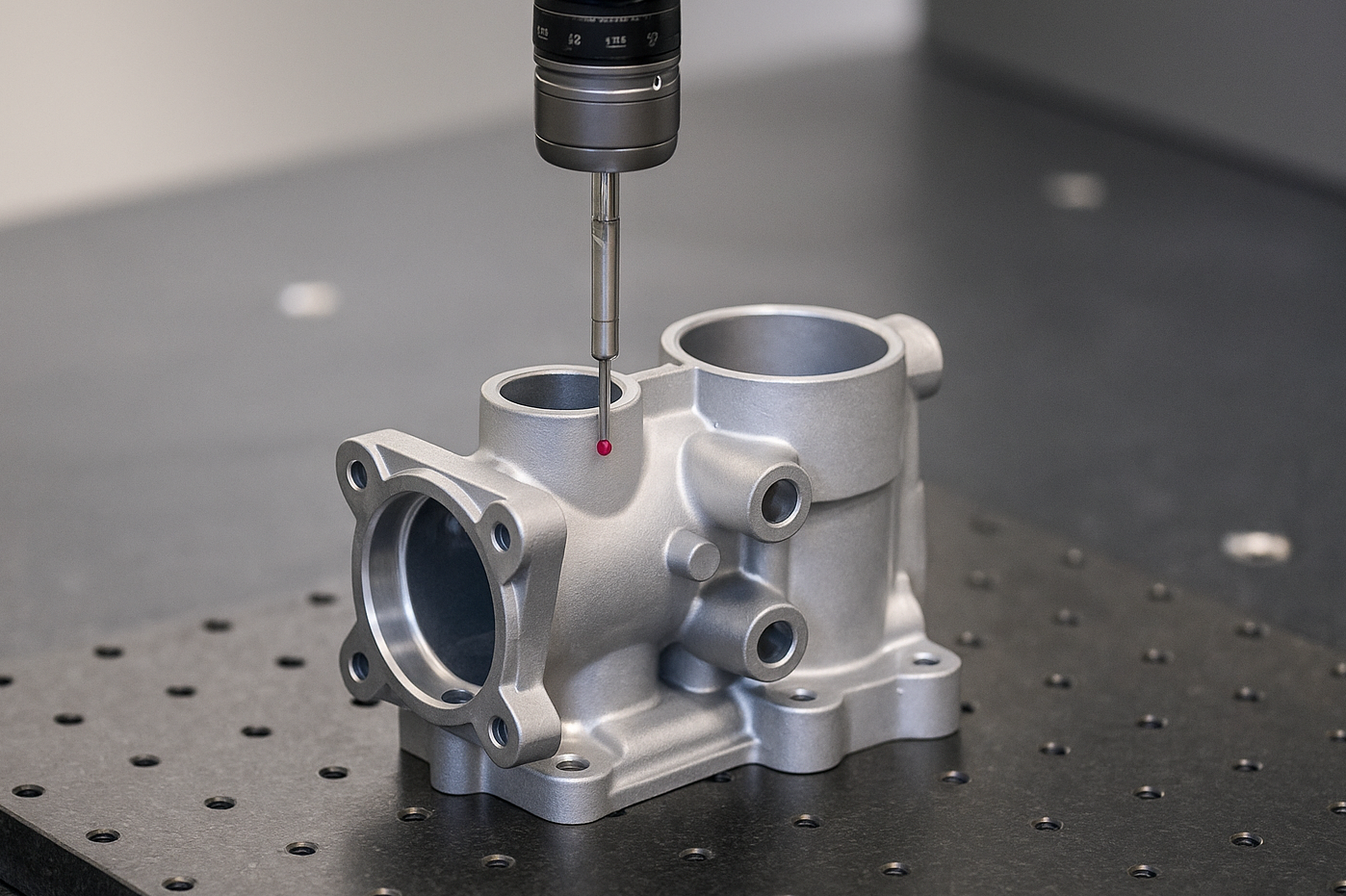

Datum References

Datums anchor measurement systems during inspection. They define starting points for GD&T features such as flatness, perpendicularity, and true position.

Why You Need Both for Accurate Machining Quotes

The CAD file communicates geometry and enables toolpath generation. The technical drawing provides critical detail for:

- Fit and function (via tolerances and dimensions)

- Manufacturing requirements (threads, finishes)

- Inspection and quality assurance (datums and notes)

Without both, assumptions can lead to delays, incorrect features, or quote revisions. Simple Machining often requests both files to provide accurate, dependable pricing.

Common Quoting Errors Due to File Submission

Here are typical mistakes that disrupt the quoting workflow:

- Submitting only a screenshot or photo of the part

- Uploading a PDF drawing without an accompanying 3D model

- Sending an STL file for CNC jobs (intended for 3D printing only)

- Omitting threads, tolerances, or revisions in the drawing

Each of these adds unnecessary time and confusion.

Best Practices for Submitting Manufacturing Files

Always Provide a STEP File for CNC Jobs

STEP files are the industry standard for 3D data exchange. They maintain precise geometry and are readable by most CAM systems. STL files, which only include triangulated surfaces, are not suitable for machining.

Include a PDF Technical Drawing for Features Requiring Control

If your part has any functional geometry or surface specification, a 2D drawing is essential to define intent beyond what is visible in 3D.

Match Revision Numbers Between Files

Inconsistent revisions between CAD and drawings cause errors in quoting and production. Always update both files to reflect the same revision level.

Use the Drawing to Define Critical Features

Don’t rely on embedded dimensions in the CAD file or screenshots. The drawing should explicitly control tolerances, threads, and surface finishes.

Review Files for Accuracy Before Uploading

Ensure all data is visible, dimensioned correctly, and consistent across files. Small errors can delay quoting by days.

Need Help Preparing Files?

Our team can assist with CAD file formatting, drawing standards, and best practices for quoting. We’re here to help ensure your parts are ready for production. We generate reference drawings FOR FREE with every CAD project & can generate full technical drawings for a flat fee per part. Learn more about our technical drawing services here

Conclusion

CAD files and technical drawings each play an essential role in the on-demand manufacturing workflow. CAD files define the shape; technical drawings define the intent. Submitting both gives your machining partner the context needed to quote quickly and produce accurately.

Not sure what to submit? Reach out to our team to ensure your files are manufacturing-ready.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

What Project Managers Need to Know About 3D Printer Resolution

Read the Article 6 minute read

6 minute read

August 20th

August 20th

How Overlooking Tolerances Can Sink Your Machining Project

Read the Article 4 minute read

4 minute read

August 4th

August 4th