- Home

- About Us

-

Industries

-

Resources

- Contact Us

Blogs and Articles

Read the latest blogs and articles and stay informed on all things Simple Machining

Sign up for the newsletter:

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th

Scaling Without Risk: On-Demand Manufacturing for Startups and SMBs

Read the Article 6 minute read

6 minute read

August 25th

August 25th

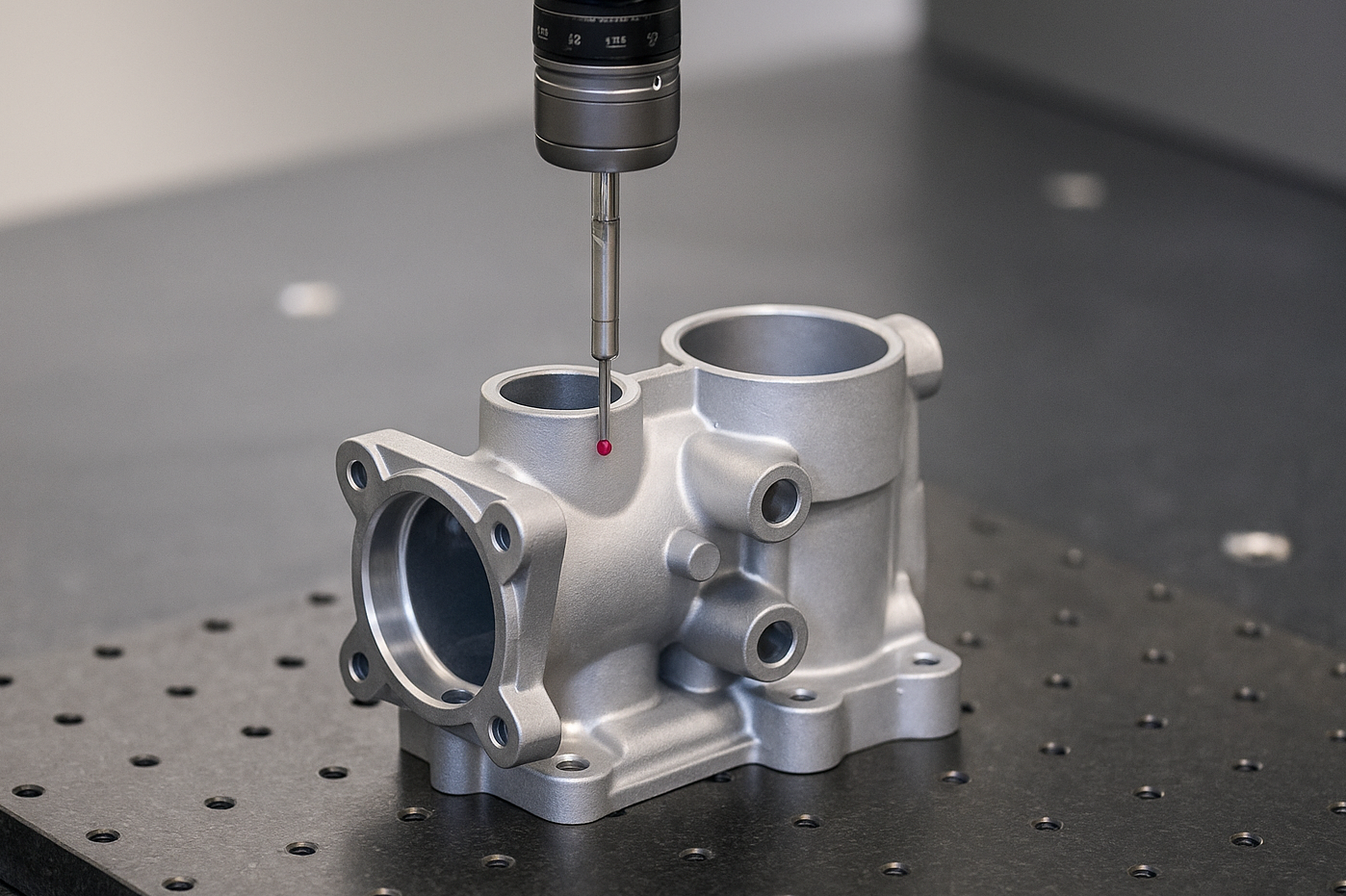

How Overlooking Tolerances Can Sink Your Machining Project

Read the Article 4 minute read

4 minute read

August 4th

August 4th

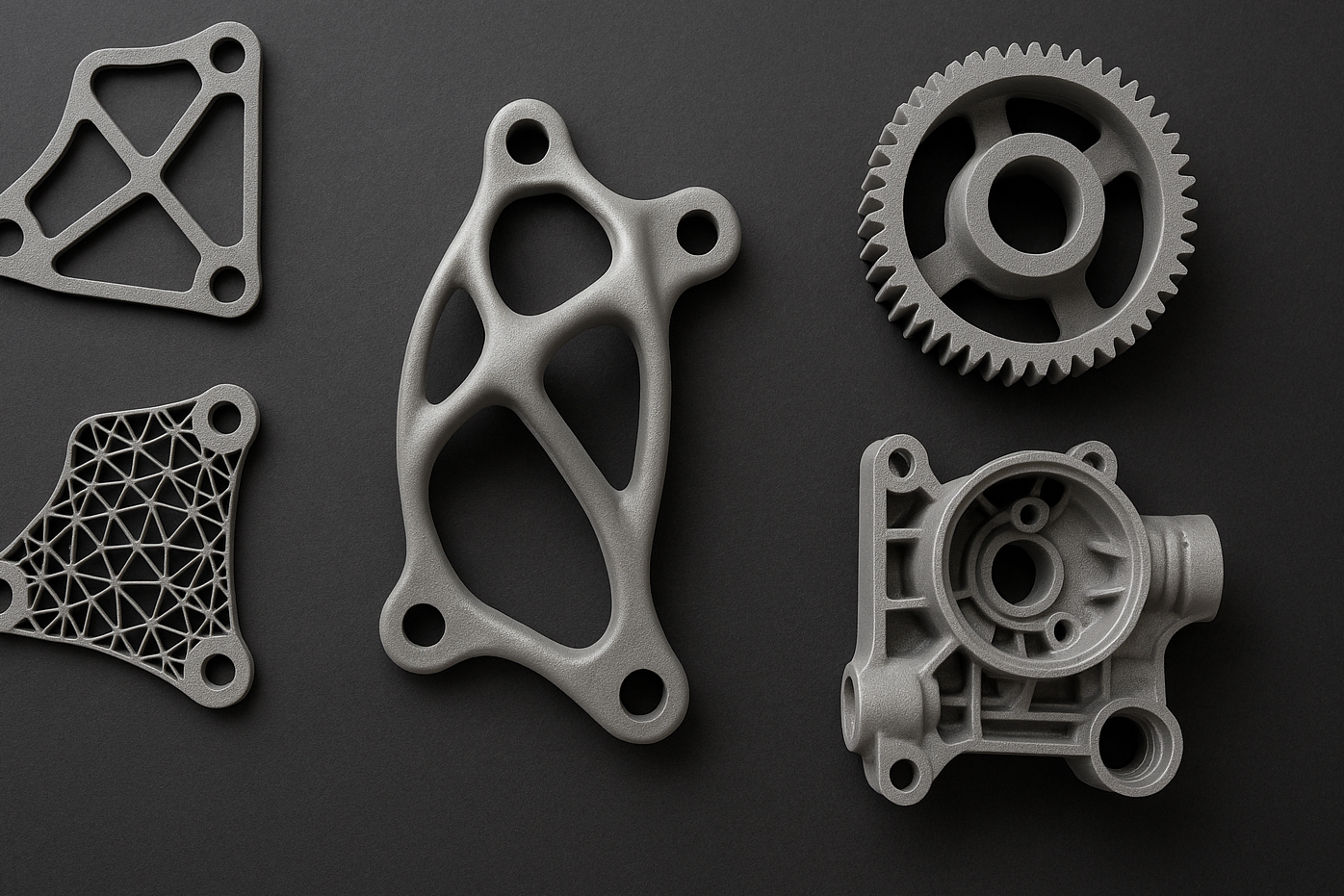

DFAM Done Right: A Practical Playbook for Modern Product Development

Read the Article 6 minute read

6 minute read

July 28th

July 28th

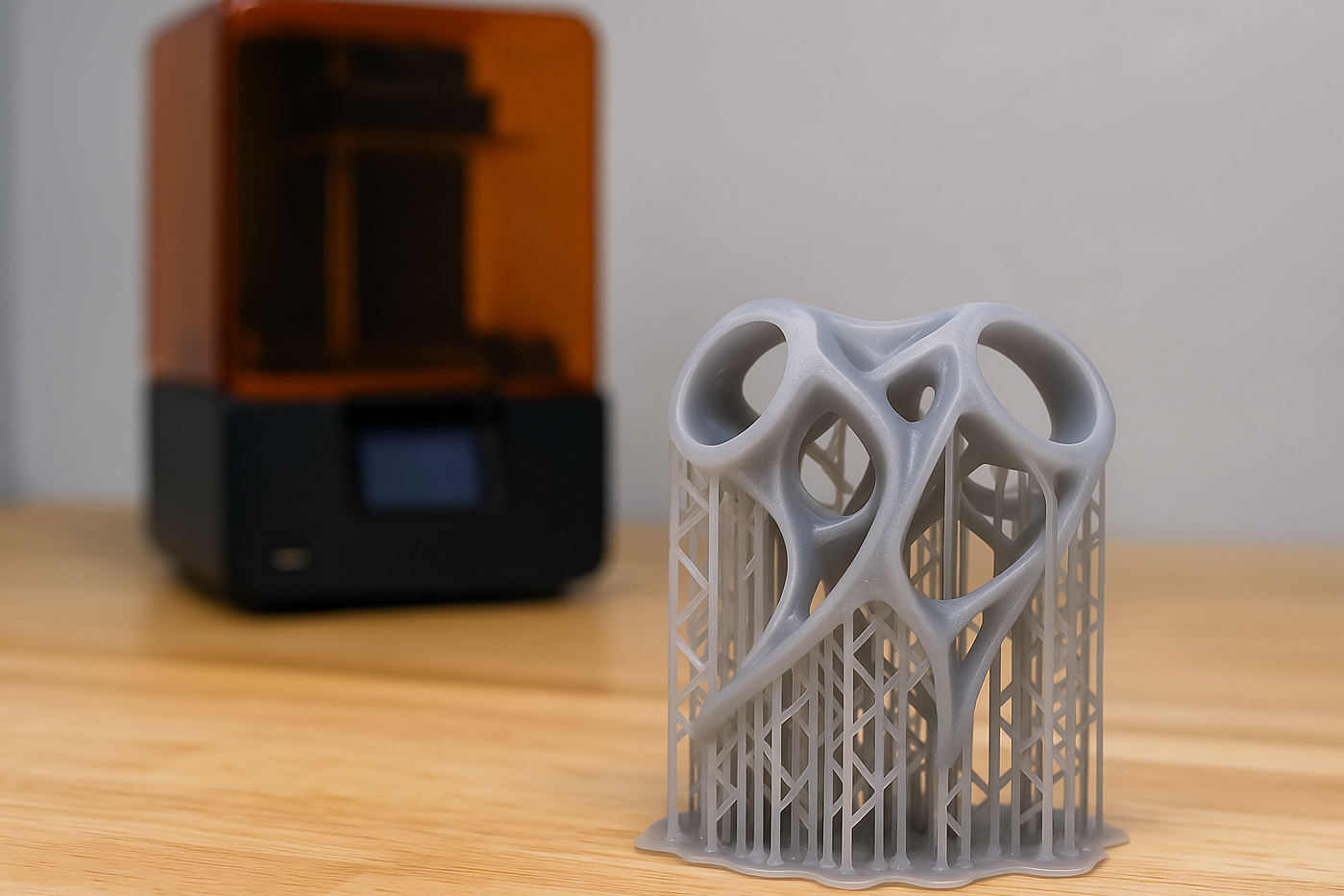

Is MJF Right for Your Project? Everything You Need to Know

Read the Article 11 minute read

11 minute read

July 14th

July 14th

Your Guide to SLS: Advantages, Materials, and Best Practices for Product Teams

Read the Article 9 minute read

9 minute read

July 7th

July 7th