- Home

- About Us

-

Industries

-

Resources

- Contact Us

Blogs and Articles

Read the latest blogs and articles and stay informed on all things Simple Machining

Sign up for the newsletter:

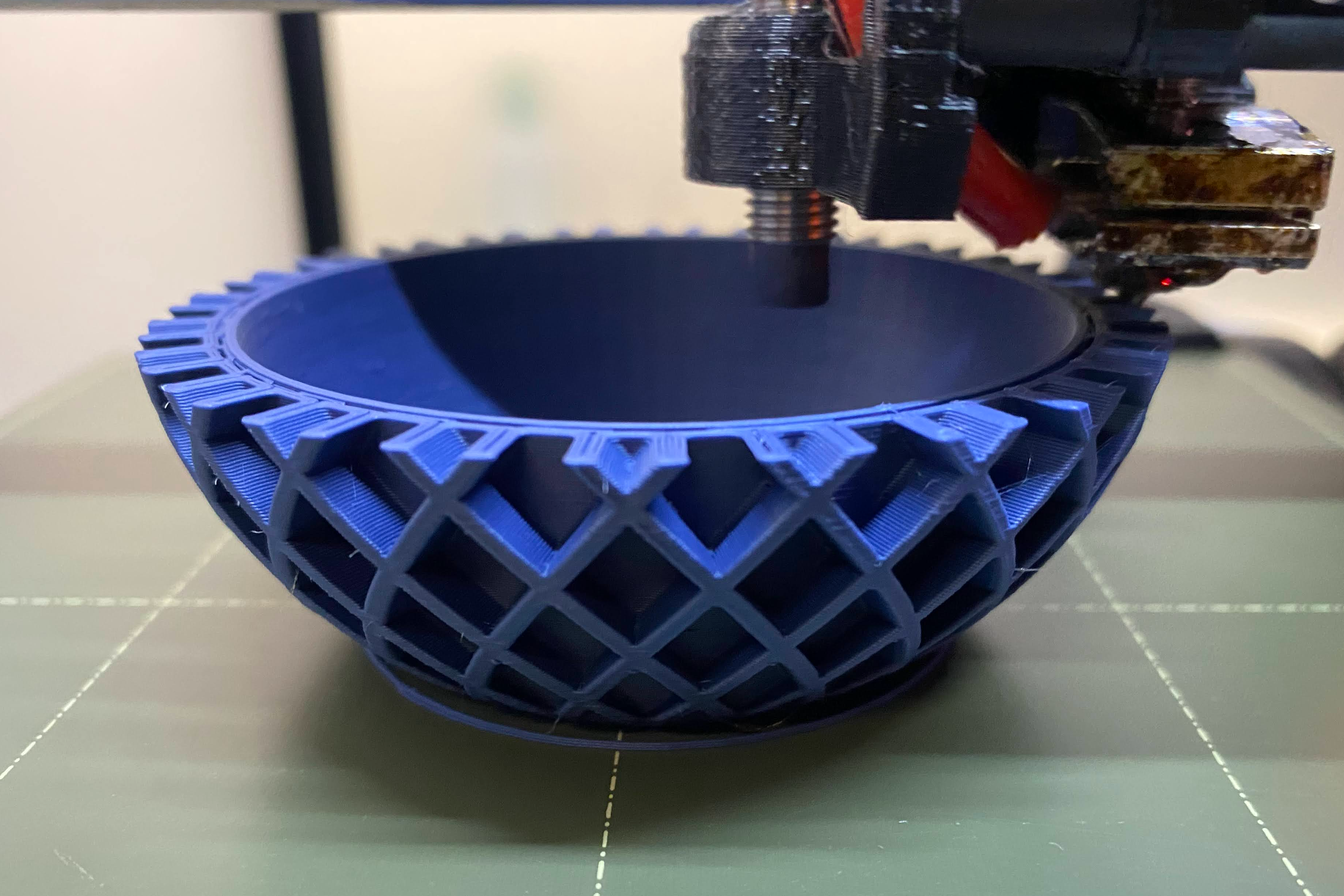

What Project Managers Need to Know About 3D Printer Resolution

Read the Article 6 minute read

6 minute read

August 20th

August 20th

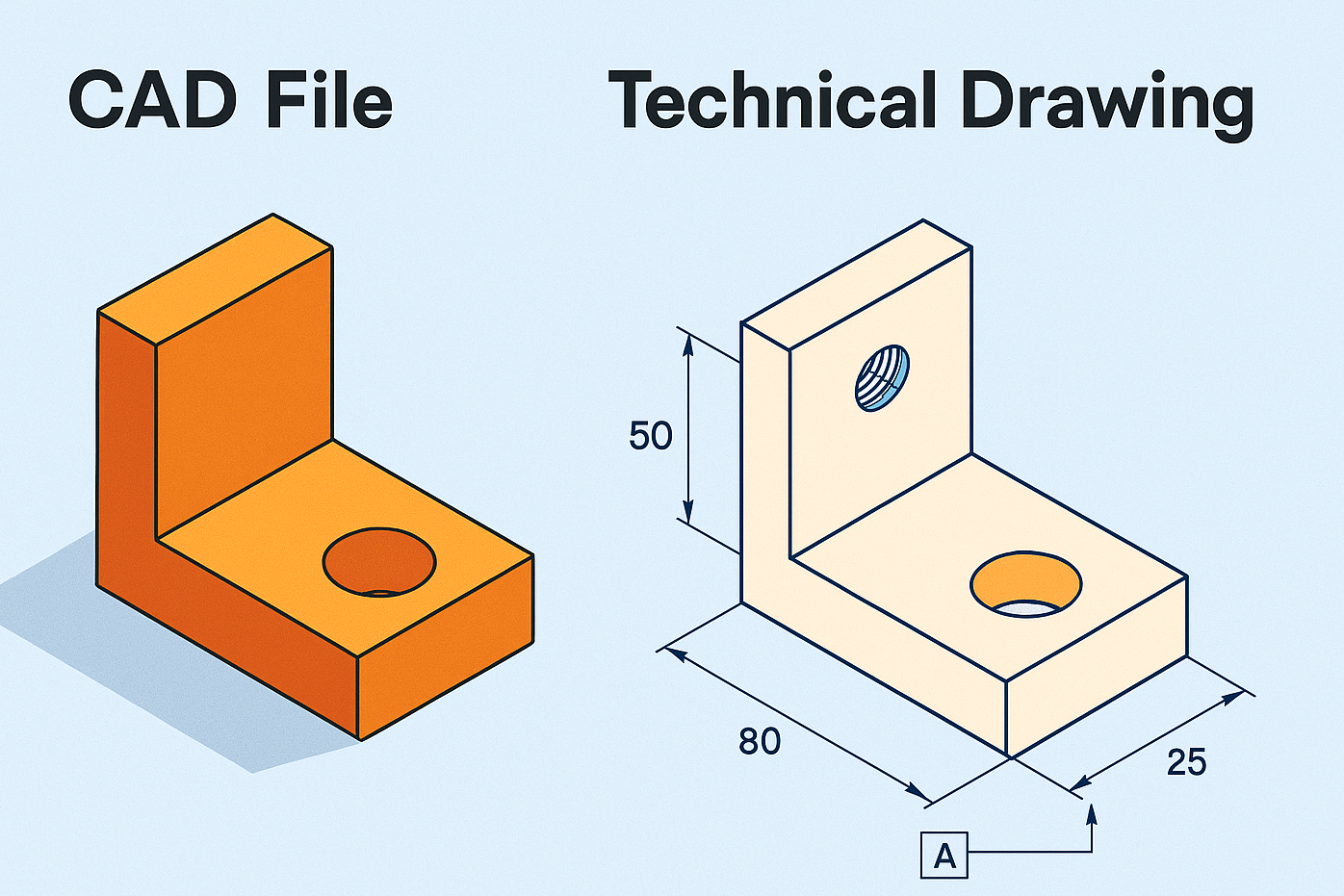

How Overlooking Tolerances Can Sink Your Machining Project

Read the Article 4 minute read

4 minute read

August 4th

August 4th

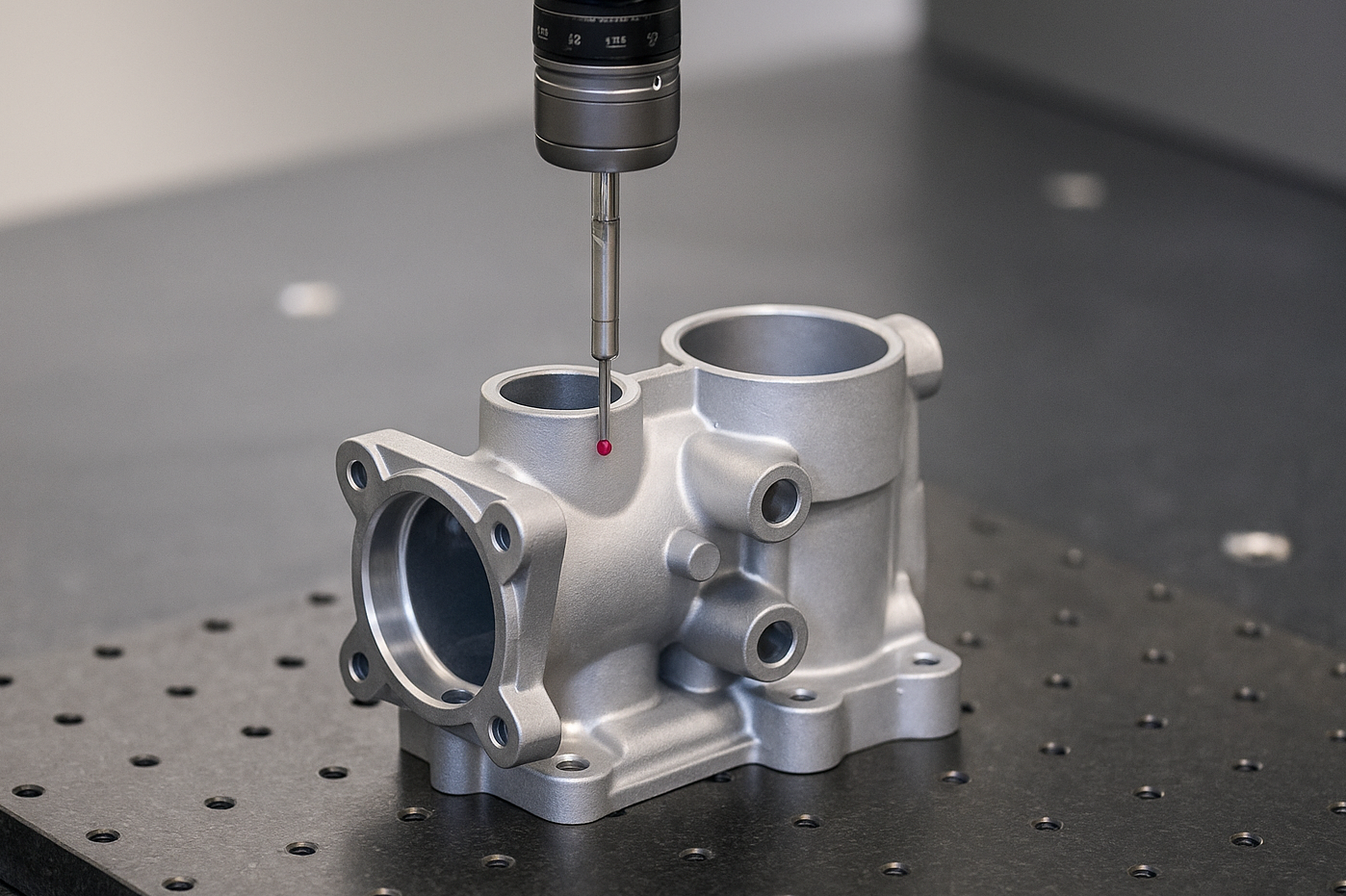

DFAM Done Right: A Practical Playbook for Modern Product Development

Read the Article 6 minute read

6 minute read

July 28th

July 28th