- Home

- About Us

-

Industries

-

Resources

- Contact Us

SLA 3D Printing Guide: Materials, Use Cases, and 6 Design Guidelines for Project Success

Published on: June 30, 2025

By: The Simple Machining Team

Stereolithography emerged in the 1980s as the first commercially viable 3D printing technology, transforming prototyping with its precision and smooth surface quality. Initially used for basic concept models, SLA quickly became essential for detailed prototypes, master patterns, and cosmetic parts across industries that demanded high-resolution results.

This guide explains how SLA works, compares it to other 3D printing methods, explores its materials and capabilities, and highlights how Simple Machining helps engineers and product developers implement SLA for both prototypes and production parts.

What Is SLA 3D Printing?

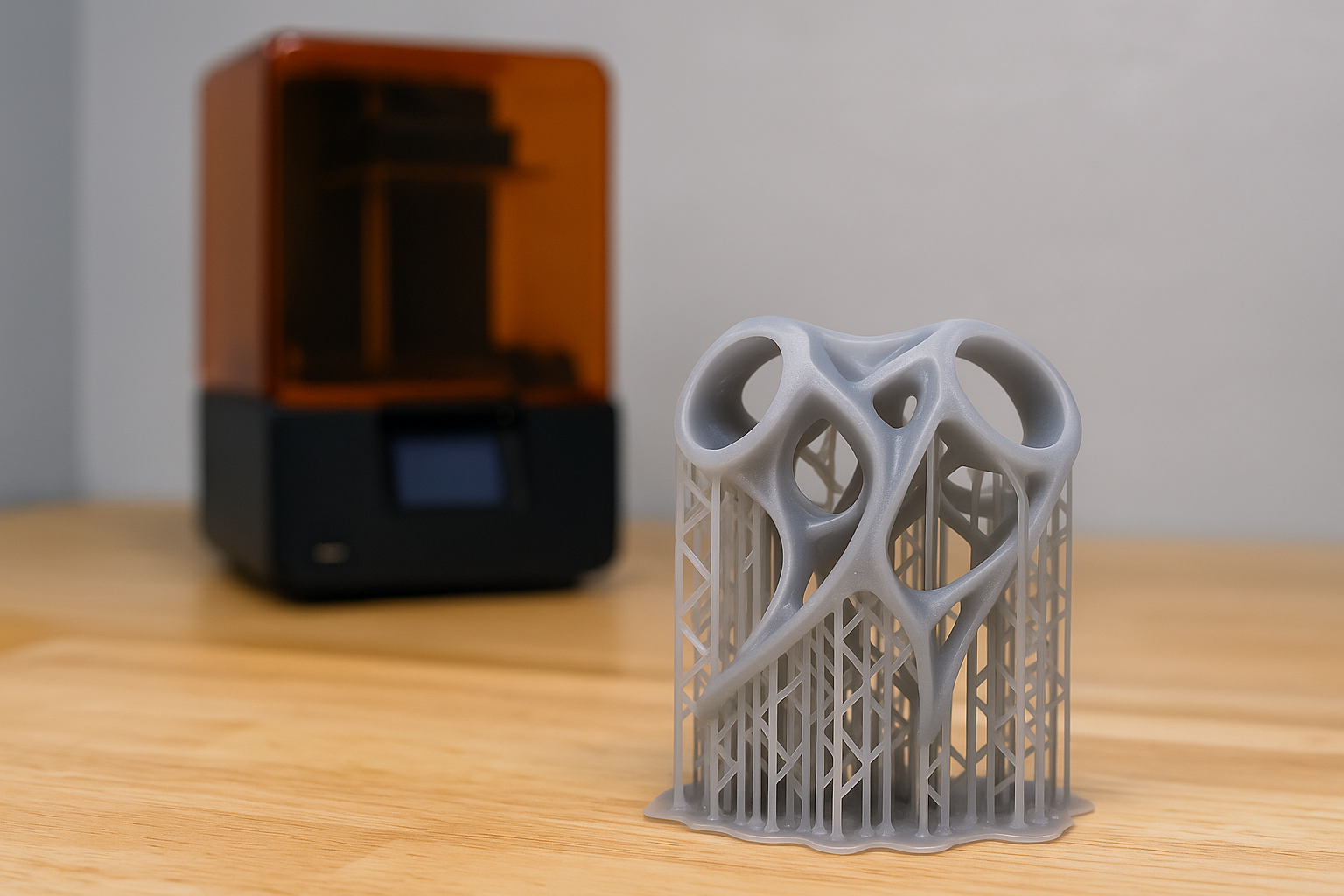

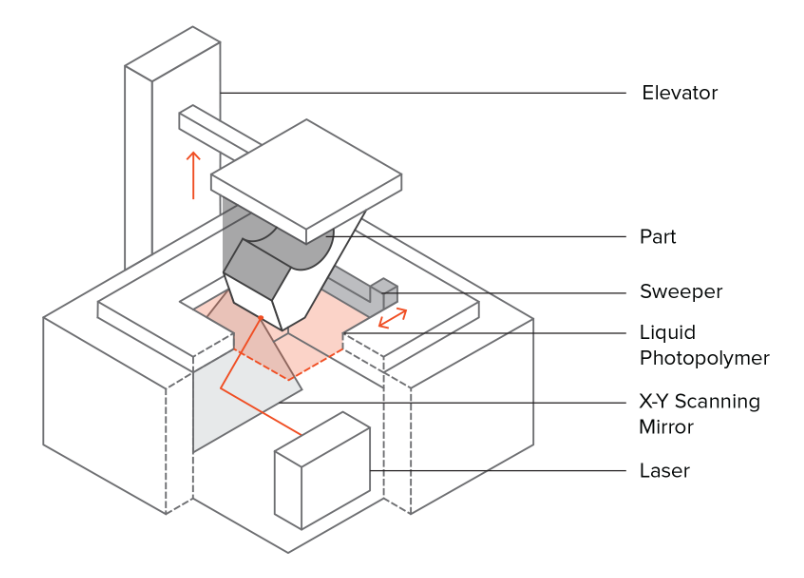

SLA is a photopolymerization printing method where a UV laser selectively cures resin in a vat. The printer constructs parts by solidifying each cross-section of the object and incrementally raising the build platform after each pass to form each layer.

SLA requires post-processing, including support removal, rinsing to clear excess resin, and UV curing to fully solidify the printed part. When polished, clear SLA resins can achieve glass-like transparency.

SLA is often chosen when a prototype needs to closely resemble a finished product in both appearance and precision. It delivers fine details, crisp edges, and smooth surfaces that surpass most other 3D printing methods, desktop or industrial. SLA also supports transparent and castable resins, making it a versatile option across industries such as medical, industrial, and consumer electronics.

How Does Resin 3D Printing Work?

Resin 3D printing, also called stereolithography (SLA) or digital light processing (DLP), uses a liquid photopolymer that hardens when exposed to a precise light source. The process works layer by layer:

- A build platform lowers into a vat of liquid resin, stopping just above the surface.

- A laser (SLA) or projected light pattern (DLP) selectively cures the resin, solidifying the cross-section of the part.

- The platform lifts to allow uncured resin to flow beneath, and the next layer is cured directly on top of the previous one.

- This cycle repeats until the full geometry is built.

After printing, the part requires rinsing in a solvent to remove excess resin, followed by post-curing under UV light to reach final strength and dimensional stability.

This workflow makes resin printing ideal for producing high-detail prototypes, functional models, and low-volume production parts with smooth surface finishes.

Key Highlights of SLA 3D Printing

Pros

- Smooth, high-resolution finish

- Accurate for tight assemblies and fine details

- A variety of materials, including clear, flexible, and biocompatible

- Repeatable quality across small batches

Cons

- UV-sensitive parts may yellow or degrade over time

- Post-processing takes time

- Higher cost per part than FDM

Additional SLA 3DP Features:

- Resolution down to ~25 microns (0.00098”)

- Resolves fine features such as textures, logos, internal channels, and sharp edges

- Smooth surfaces with minimal post-processing

- Great for snap-fits, late-stage prototypes, tight-fitting assemblies, and aesthetic parts

- Supports a wide range of specialty materials, such as resins with a UL94-V0 flammability rating

SLA Resin Options

Material selection directly impacts the strength, surface finish, and durability of SLA prints. The availability of high-temperature and castable resins expands their use across industries like automotive, medical, and jewelry. SLA materials include:

Standard Resins: Great for draft prototypes and visual models. Examples include Formlabs Standard Resin or Anycubic Basic Resin, which offer good surface detail at a lower cost.

Engineering Resins: Designed for added toughness, heat resistance, or impact strength. Options like Formlabs Tough 2000 Resin or Siraya Tech Blu Resin support functional snap-fits, enclosures, and load-bearing features.

Clear Resins: Perfect for transparent parts, lenses, and light pipes. Clear materials such as Formlabs Clear Resin or Elegoo Transparent Resin deliver excellent optical clarity with post-polishing.

Biocompatible Resins: Essential for medical and dental applications, including surgical guides or dental models. Resins like Formlabs Dental SG Resin are certified for patient contact with proper post-curing.

High-Temperature Resins: Suitable for automotive and industrial tooling applications. Resins like Formlabs High Temp Resin can withstand temperatures exceeding 230 °C, enabling short-run functional testing or mold-making.

Castable Resins: Used by jewelers and miniaturists to produce patterns for investment casting. Castable Wax Resin, for example, burns out cleanly and delivers high-resolution features for precious metal casting.

How Does SLA Compare?

Vs. Fused Deposition Modeling (FDM): SLA achieves smoother finishes and far finer detail, making it superior for visual prototypes, though it comes with higher material costs and smaller build envelopes compared to FDM's larger, less detailed parts. For more details on FDM, read our deep dive.

Vs. Selective Laser Sintering (SLS): SLA requires support structures during printing and produces parts that are not as mechanically robust as SLS, but delivers vastly superior surface quality and sharp visual detail for aesthetic-driven prototypes.

Vs. Multi-Jet Fusion (MJF): Multi-Jet Fusion excels for strong, functional end-use parts with great durability, while SLA stands out for cosmetic excellence and intricate feature reproduction, making it the best choice for visual validation models.

Read a full comparison with our recommendations here.

Technical Specs

- Typical SLA machine capabilities:

- Layer thickness: 25 to 100 microns

- XY accuracy: ±0.1 mm + ~ 2% per inch (Z-Axis)

- Build volume: 736mm x 635mm x 533mm

- Tree-like lattice supports are required for overhangs

- Required post-curing improves strength and stability

When is SLA the right choice?

SLA is the go-to technology when precision, aesthetics, and tight tolerances are paramount. Its ultra-smooth surface finish, high resolution, and wide material versatility make it a standout for many industries and product teams. SLA supports validation of both form and fit, reducing the risk of costly redesigns later in production. Typical use cases include:

🔍 Visual models and showpieces: SLA’s fine detail, capable of achieving layer heights down to 25 µm, allows for sharp lettering, logos, and realistic surface textures. Designers can present prototypes that accurately reflect final products, making it easier to communicate ideas to clients or stakeholders.

📏 Tight-tolerance enclosures and fittings: SLA can maintain tolerances of ±0.1 mm, which is critical when testing complex assemblies, snap fits, or precise internal geometries. This is especially valuable for electronics housings or connector prototypes, where small deviations can impact assembly.

🔬 Transparent components and optics: With clear resins, SLA produces functional transparent components such as light guides, optical covers, or fluidic channels. The high clarity in these parts allows for functional testing of illumination, flow, or optics early in the design cycle, saving time and eliminating the need for custom machining.

🎯 Marketing assets and investor prototypes: SLA delivers near-production-quality parts quickly, often within days. This speed enables teams to showcase polished, brand-aligned prototypes for presentations, trade shows, or funding pitches without waiting for full tooling.

With fast turnaround, high detail, and dependable accuracy, SLA is a cornerstone of rapid prototyping and low-volume production, helping teams move confidently from concept to product.

Common Industry Applications

While not an exhaustive list, these examples highlight how our customers across industries have successfully used SLA 3D printing.

Medical & Dental: SLA produces surgical guides and anatomically accurate models that help clinicians plan procedures with precision and confidence.

Consumer Products: From cosmetic prototypes to early marketing samples, SLA allows teams to present product aesthetics and branding clearly, before committing to tooling or mass production.

Electronics: Thanks to its high resolution and ability to print in clear or translucent resins, SLA is well-suited for housings, connectors, light pipes, and other small components that require tight tolerances.

Jewelry & Miniatures: SLA supports castable and highly detailed patterns, streamlining the transition from design to casting and enabling intricate features with exceptional accuracy.

Looking Ahead

The SLA market is projected to grow from around $4 billion in 2025 to $8.6 billion by 2030, driven by advancements in resin formulations, faster curing technologies, and improved part performance. Key industries such as automotive, healthcare, and consumer products are expected to expand their use of SLA to accelerate development cycles, validate intricate designs, and bridge the gap between prototyping and production.

General Guidelines When Designing for Stereolithography

While SLA 3D printing is known for precision and high detail, there are best practices to ensure parts are both manufacturable and functional:

Wall Thickness: Maintain a minimum wall thickness of 0.5 mm for rigid resins and at least 1 mm for flexible resins to prevent warping or breakage during post-processing.

- Supports and Overhangs: SLA requires supports for overhangs and delicate features. Reducing steep angles in your design can minimize support marks, simplify cleanup, and reduce printing costs.

- Holes and Channels: Incorporate escape holes for draining uncured resin, especially in hollow or enclosed parts, to prevent deformation and trapped resin.

- Tolerances: SLA prints typically achieve ±0.1 mm accuracy. However, feature accuracy may vary based on geometry and orientation. Additionally, SLA prints experience ~1–2% shrinkage during post-curing, which should be compensated for in the design

- Orientation Considerations: Orient your part to reduce support material and protect cosmetic surfaces. In most cases, this means placing large flat areas parallel to the build plate to improve surface quality and print success.

- Surface Finish: For optical clarity with clear resins, plan for light sanding or coating after curing.

Need help with preparing your design for SLA 3D Printing? Learn more about our Design for Manufacturing (DFM) services.

Why Choose Simple Machining for SLA

At Simple Machining, we guide you through resin selection, file preparation, and print optimization to get the most out of SLA. Whether you're building a new prototype, iterating on an existing design, or ready to start low-volume production, our team delivers fast, high-quality parts that meet your performance and visual requirements.

Start your project today by uploading a file or requesting a manual quote.

FAQs

What does SLA stand for in 3D printing?

SLA stands for Stereolithography Apparatus. The name comes from the Greek words “stereo” meaning solid, “litho” meaning stone, and “graphy” meaning writing.

What tolerances can SLA achieve?

Typically ±0.1 mm + 2% per inch in the Z-Axis, depending on part geometry.

How strong are SLA parts?

Standard SLA resins tend to be brittle. Engineering-grade resins offer improved toughness and durability.

Can I use SLA for production?

Yes. SLA is suitable for small-volume production, especially for cosmetic or low-stress parts.

Do SLA prints require supports?

Yes. Proper part orientation can help minimize the amount of support needed.

Is SLA good for transparent parts?

Yes. Using clear resins in combination with polishing, SLA parts can closely simulate the clarity of polycarbonate.

What are other names for SLA?

SLA is also known as stereolithography, vat photopolymerization, optical fabrication, photo-solidification, or resin printing.

Key Takeaways

- SLA offers unmatched surface quality and detail

- Useful for appearance-focused and precision prototypes

- Suitable for small production runs of non-load-bearing parts

- Offers flexibility through a wide variety of specialized resins

Click here to learn more about our SLA 3D Printing Service.

Looking for more insights?

Sign up for the newsletter:

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th

Scaling Without Risk: On-Demand Manufacturing for Startups and SMBs

Read the Article 6 minute read

6 minute read

August 25th

August 25th