- Home

- About Us

-

Industries

-

Resources

- Contact Us

Scaling with On-Demand Manufacturing for Startups and SMBs

Published on: September 15, 2025

By: The Simple Machining Team

Scaling production is one of the biggest hurdles for startups and small to medium-sized businesses (SMBs). Costs, lead times, and quality risks can multiply quickly. On-demand manufacturing provides a practical solution by enabling companies to grow in controlled steps without committing to high-volume risks.

Why Is Scaling Production Challenging for Startups?

Scaling is not just about making more parts; it’s about doing so reliably and cost-effectively. Startups and SMBs often face cost overruns from tooling and setup fees, supply delays caused by fragile supply chains, and quality issues that multiply when production volumes rise. For young companies, these challenges can stall momentum at the exact moment growth is needed most.

How Does On-Demand Manufacturing Reduce Risk?

On-demand manufacturing gives startups a path to scale safely by offering flexibility, cost control, and faster market entry. Companies can order scalable quantities, from prototypes to small batches to bridge runs. Shorter lead times support testing and launches, while the absence of large tooling investments keeps upfront costs low. By accessing a broader supplier network, startups also reduce the risk of relying on a single source.

On-demand manufacturing reduces risk by letting companies scale gradually. Instead of large upfront investments in tooling or inventory, businesses order in smaller batches, refine designs quickly, and keep capital free for growth.

What Are the Steps to Scale from Prototype to Production?

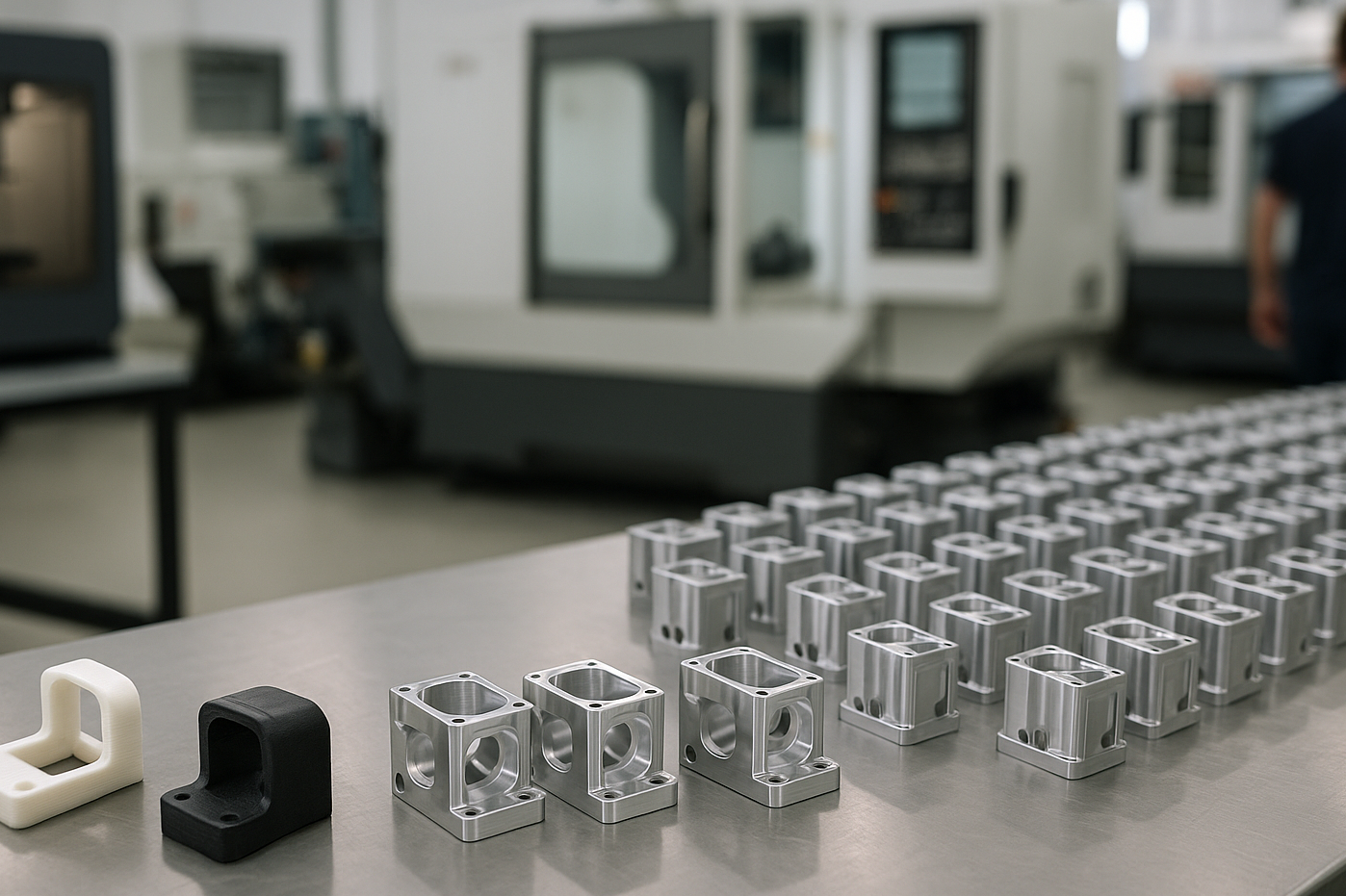

Successful scaling usually unfolds in stages. Early on, prototype runs validate design and functionality. Once confidence grows, companies move into low-volume batches to test markets and gather feedback. Bridge production comes next, where hundreds or thousands of units are produced to prepare for market launch. Finally, businesses can transition into high-volume manufacturing once demand is stable and predictable.

Prototype Runs: Validate design and functionality.

Low-Volume Batches:Test markets and gather customer feedback.

Bridge Production: Produce hundreds or thousands of units before committing to mass production.

High-Volume Manufacturing: Transition once demand is stable and predictable.

Bridge production is a low-volume manufacturing stage between prototypes and full production. It allows startups to produce hundreds or thousands of units for market testing without committing to high-volume tooling.

Is On-Demand Manufacturing More Expensive?

Understanding how costs change is critical to scaling successfully. Tooling costs are high at the start but spread across more units as volumes grow. Smaller material orders are more expensive per unit, while bulk orders reduce overall costs. Frequent setup and labor adjustments add expense in low-volume runs. As production scales, inspections and quality assurance become increasingly important to maintain consistency.

On-demand manufacturing can cost more per unit than mass production, but it avoids upfront tooling expenses and large inventory risks. For startups, the total cost is often lower because capital is preserved until demand is proven.

How Do Small Businesses Scale Manufacturing?

Minimizing risk requires adopting practical scaling strategies. Designing for manufacturability helps reduce complexity and makes parts easier to produce. Planning realistic lead times ensures production, shipping, and inspection are all accounted for. Strong supplier relationships improve communication and reduce the likelihood of costly delays. Quality checks introduced early in the process help catch problems before they multiply.

Small businesses scale manufacturing by starting with prototypes, moving into low-volume production, and partnering with on-demand suppliers. This phased approach balances cost, quality, and flexibility while reducing risk.

When Should a Company Switch to Mass Production?

On-demand manufacturing isn’t always the final step. As companies grow, they should consider moving into high-volume production when per-unit costs outweigh the benefits of flexibility. A stable and predictable demand profile makes large tooling investments worthwhile, and at this stage, mass production becomes more efficient.

Companies should switch to mass production when demand is stable, volumes exceed thousands of units, and the cost of tooling can be spread across a large production run.

Partnering with Simple Machining to Scale Confidently

Simple Machining helps startups and SMBs bridge the gap between prototypes and production. Our on-demand services include prototyping in multiple materials and processes, low-volume production with fast lead times, and quality assurance tailored for early-stage needs. We also guide businesses through the transition to high-volume manufacturing when the time is right.

Conclusion

Scaling should be a growth opportunity, not a risk. On-demand manufacturing gives startups and SMBs the agility to move from prototypes to production with confidence, speed, and cost control. With the right partner, growth becomes less about risk and more about possibility.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

Scaling Without Risk: On-Demand Manufacturing for Startups and SMBs

Read the Article 6 minute read

6 minute read

August 25th

August 25th