- Home

- About Us

-

Industries

-

Resources

- Contact Us

FDM, SLA, SLS, and MJF Compared: How to Choose the Right 3D Printing Process

Published on: June 15, 2025

By: The Simple Machining Team

Choosing the proper 3D printing process can define the success of your project. With multiple technologies available—each with distinct advantages and limitations—it’s essential to align the process with your design goals, functional requirements, and production needs.

Read our In-Depth Guide on each Process:

FDM 3D Printing: Pros, Cons, and Practical Applications

SLA 3D Printing Guide: Materials, Use Cases, and 6 Design Guidelines

Your Guide to SLS: Advantages, Materials, and Best Practices for Product Teams

Is MJF Right for Your Project? Everything You Need to Know

In this 3D printing process comparison, we examine four commonly used additive manufacturing technologies: Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Multi Jet Fusion (MJF). This guide is intended to help engineers, product developers, and procurement teams make well-informed decisions based on the strengths, trade-offs, and ideal use cases of each method.

Learn how on-demand 3D printing supports fast, iterative development in our overview Guide to On-Demand 3D Printing.

Comparing FDM, SLA, SLS, and MJF

Each 3D printing process excels in different areas. While budget and color matter, other factors such as resolution, material compatibility, and production throughput often have a larger impact on project outcomes.

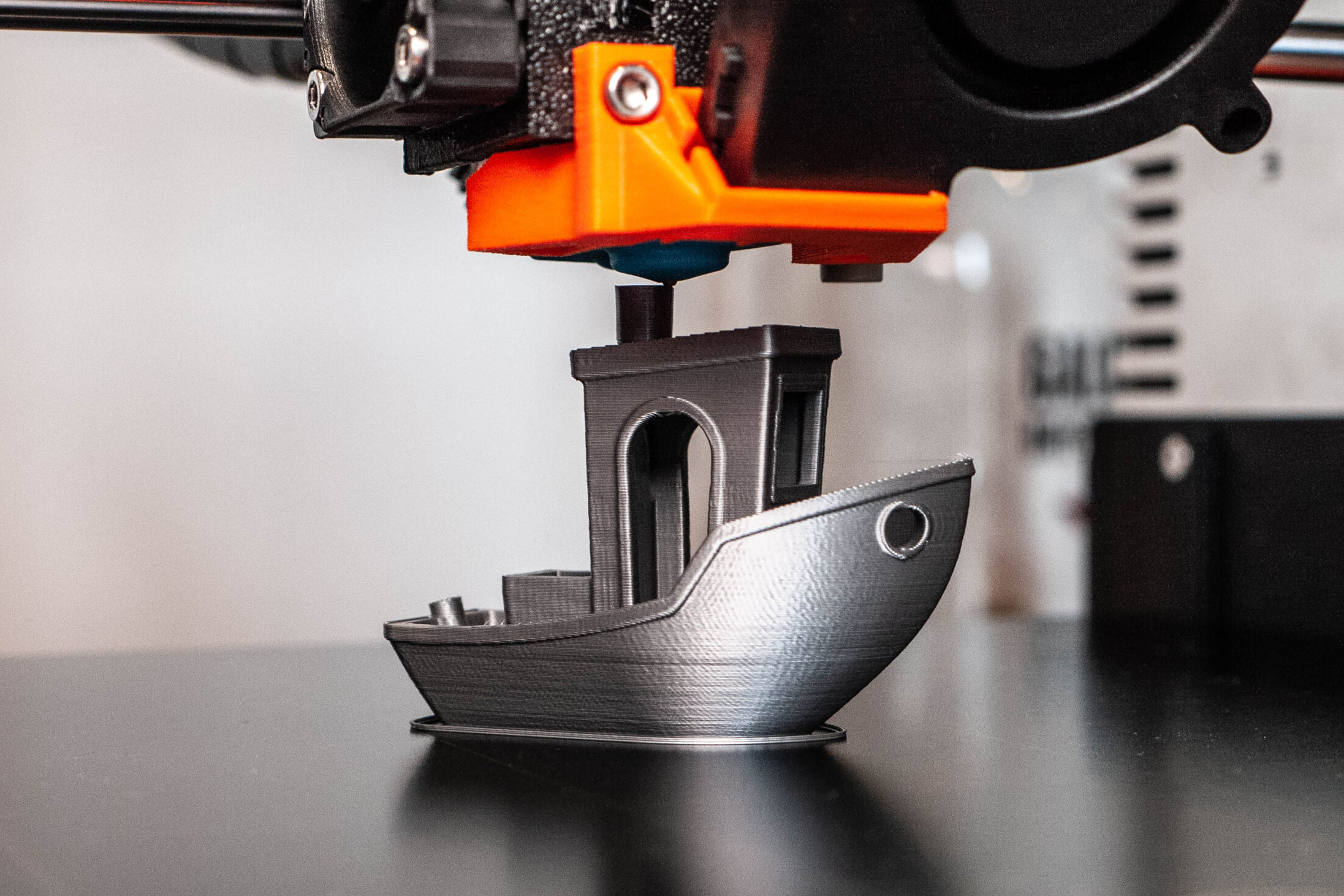

Fused Deposition Modeling (FDM)

FDM uses a heated nozzle to extrude thermoplastic material in layers. It is well-suited for low-cost prototyping and manufacturing larger parts, commonly utilizing materials like PLA, ABS, ASA, and nylon blends. FDM provides fast turnaround times, though it typically produces visible layer lines and has limitations in achieving fine detail resolution.

FDM is especially effective for iterative testing and mechanical mock-ups, where functional validation matters more than surface finish.

Stereolithography (SLA)

SLA cures liquid resin with a UV laser, producing high-resolution parts with smooth surface finishes. It is ideal for applications where precision and aesthetics are critical. While SLA offers relatively large build volumes compared to some other processes, it is limited by the brittleness of available materials.

SLA is a top choice for visual models, fit assessments, and applications where fine detail and precision are critical.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) fuses powdered nylon using a high-powered laser, producing durable parts without the need for support structures. It excels at creating complex geometries and components designed for high-load applications. This is a great choice for Print-in-Place models (PiP) such as articulated models. Common materials include PA12, PA11, and various composites, though parts may require post-processing due to a naturally coarse surface finish.

SLS is particularly well-suited for functional prototypes that need to replicate the strength and performance of production-grade parts.

Multi-Jet Fusion (MJF)

Multi-Jet Fusion (MJF) employs a fusing agent combined with infrared light to produce strong, detailed parts with excellent uniformity. It commonly uses materials such as PA12, PA11, and TPU. MJF is particularly well-suited for scalable, low to medium volume production runs thanks to its more consistent part quality and efficient throughput across batches.

MJF excels in speed, consistency, and resolution, making it ideal for bridging prototyping with low-volume manufacturing.

What Process Should I Use For My First Prototype?

FDM is usually the best choice for your first prototype because it provides fast, functional models at a low cost.

SLA is a great option for when you need ultra-high detail and presentation-ready parts with smooth surfaces that FDM cannot deliver.

SLS and MJF are preferred for functional prototypes that require strength and complexity similar to final production parts. These should generally only be used for first prototypes if the designs are complex and may suffer from dimensional accuracy.

Our Recommendation: FDM

I Need a Strong Part, Which Process Should I Choose?

FDM can create strong parts depending on geometry and material selection, but overall a process it’s not the most optimal choice.

SLA is similar to FDM where it depends highly on the geometry and material selection

SLS leads in strength and mechanical integrity, making it a preferred choice for functional testing and end-use applications.

MJF rivals SLS in performance while offering greater repeatability and efficiency for batch production.

Our Recommendation: SLS or MJF

Which 3D Printing Process Is the Most Cost-Effective?

FDM is the budget-conscious choice for basic prototyping and functional parts.

SLA, while more expensive, delivers excellent value through its high level of detail and superior surface finish, ideal for presentation-quality models.

SLS and MJF typically involve higher upfront costs but offer better durability and become more cost-effective when scaled for production.

Our Recommendation: FDM or SLS

Why Should I Care About Surface Finish For My Prototypes?

Surface finish plays a critical role in assembly fit, user interaction, and visual presentation. A well-finished prototype is easier to evaluate for real-world use and often requires fewer modifications before transitioning to production. If surface quality is a top priority, SLA is a leading choice due to its smooth, detailed output straight off the printer.

Our Recommendation: SLA

Which Process Should I Choose for Industrial Applications?

FDM is well-suited for automotive concepts, production jigs, and low-fidelity mockups, especially when cost efficiency and turnaround speed are key.

SLA is ideal for dental models, master patterns, design validation, and trade show visuals that demand high resolution and a premium surface finish.

SLS is preferred for aerospace, automotive, and medical components that require complex geometries and strong, load-bearing performance.

MJF is commonly used in consumer electronics, healthcare devices, and short-run production, offering excellent part consistency and scalability.

Our Recommendation: Highly depends on your needs. To get Expert guidance, contact us.

Looking for Flexibility? These are the Most Versatile 3D Printing Processes

When it comes to material range and application flexibility, FDM and SLA lead. FDM supports a broad selection of thermoplastics—from basic PLA and ABS to reinforced composites—paired with large build volumes and short lead times. SLA offers unmatched specialization, with resins tailored for water resistance, flame retardance, or biocompatibility. While SLS and MJF are strong performers, they are limited to a narrower set of nylon-based materials.

Our Recommendation: FDM or SLA

What if I Need a Small-Batch Run or Am Ready for Production?

FDM offers solid repeatability and fast turnaround for multiple iterations, but it struggles to deliver cost efficiency at scale—even in small-batch quantities.

SLA is generally not ideal for batch production unless a specific material property or resolution requirement justifies its use. High part quality comes at the expense of higher costs and lower throughputs.

SLS is well-suited for short-run manufacturing. Because it does not require support structures, parts can be densely packed not only across the build plate but also stacked along the Z-axis, maximizing the use of the entire build volume.

MJF is the strongest option for small-batch and even low-volume production. Like SLS, it requires no support material, allowing parts to be efficiently nested and stacked throughout the entire build volume (including Z-Axis). This capability, combined with high part yields with no increase in print time, makes MJF the most scalable process among the four. When material, size, and model complexity requirements align, some manufacturers even use MJF for end-use production.

Our Recommendation: MJF

How Simple Machining Supports Unique Needs

Simple Machining offers all four major 3D printing processes—FDM, SLA, SLS, and MJF. With instant quoting, convenient Bay Area pickup, and reliable national delivery, we make on-demand manufacturing straightforward and tailored to your project. Our carefully curated material selection is continuously updated to meet the most common and specialized needs across industries, enabling us to support a diverse range of applications. This is how we help to deliver on our guiding statement: Manufacturing Made Accessible.

Explore how Local Bay Area pickup can cut lead times by up to 4 business days

Conclusion

No single 3D printing process fits every application. Understanding the strengths and limitations of FDM, SLA, SLS, and MJF enables more informed decisions, enhances prototype and product performance, and helps bring ideas to market faster.

Upload your CAD file today for a custom quote and expert recommendation.

Key Takeaways

FDM: Cost-effective and versatile for functional prototypes with a wide range of thermoplastic materials.

SLA: Best for high-detail, smooth-surface parts requiring specialized materials and precision.

SLS: Ideal for strong, complex functional parts with efficient use of the entire build volume.

MJF: Most scalable for small-batch production with excellent speed, consistency, and nesting efficiency.

Strength, cost, finish, materials, and quantity affect how parts work and fit in the final product, so choosing the right process is key to ensuring project success.

Choosing the wrong process can increase costs and extend development times—risks that startups and SMBs cannot afford.

Simple Machining delivers tailored support and access to all major 3D printing technologies.

Looking for more insights?

Sign up for the newsletter:

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th

Scaling Without Risk: On-Demand Manufacturing for Startups and SMBs

Read the Article 6 minute read

6 minute read

August 25th

August 25th