- Home

- About Us

-

Industries

-

Resources

- Contact Us

FDM 3D Printing: Pros, Cons, and Practical Applications

Published on: June 23, 2025

By: The Simple Machining Team

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing processes today. Known for its accessibility and low cost, FDM is a practical choice for engineers and product teams looking to prototype quickly. However, as with any production method, FDM has its trade-offs.

This guide delves into how FDM works, where it excels, and when to consider alternatives based on performance and production goals.

Other Related Guides

Read our comparison guide on additive processes with recommendations

Learn More: Understanding 3D Printing Infill for Better Part Design

What Is FDM 3D Printing and How Does It Work?

Fused Deposition Modeling (FDM) is a 3D printing process that builds parts by melting and extruding thermoplastic filament through a heated nozzle. Material is deposited layer by layer, and each layer bonds as it cools. Due to its low cost, material variety, and quick turnaround, FDM is commonly used for early prototypes and functional parts.

What Are The Pros of FDM 3D Printing?

Cost-Effectiveness for Prototyping and Low-Volume Production

FDM offers one of the lowest entry points for 3D printing. Compared to CNC machining or injection molding, FDM requires minimal setup time and no custom tooling. This makes it especially appealing for rapid prototyping and short production runs.

Easy to Use and Widely Accessible

FDM printers are becoming widely available, with many offering plug-and-play usability. This has lowered the barrier for engineers and startups to iterate quickly, driving down material costs and making manufacturing even more accessible.

Versatile Material Options

From general-purpose PLA to engineering-grade thermoplastics like Nylon PA6, FDM supports a wide range of materials tailored to different functional needs. Common options include PLA, ABS, and ASA, along with reinforced filaments such as carbon fiber-filled PLA (PLA-CF) and glass-filled ABS (ABS-GF).

We rank FDM 1st in versatility and ease of use compared to the other 3D printing processes.

Cons of FDM 3D Printing

Surface Finish and Resolution Limitations

FDM builds parts by stacking melted thermoplastic in layers. This approach often results in visible layer lines, especially on curved surfaces. Compared to higher resolution technologies like SLA or MJF, FDM generally offers lower resolution and less smooth finishes. For applications where appearance is important, post-processing methods like sanding or vapor smoothing may be required to improve the surface quality.

At Simple Machining, our FDM service offers layer resolutions between 100 and 250 microns.

Further Reading: Learn more about 3D printing resolutions here

Mechanical Property Constraints

FDM parts can be weaker along the vertical axis, also known as the Z-axis, due to their anisotropic nature, which can significantly impact final performance (Somireddy & Czekanski, 2020), especially for tall or thin parts.

To address this, experienced CAD designers significantly reduce or alleviate this issue by planning for these limitations early in the design process by considering part function, optimizing print orientation, reinforcing structural features, and selecting materials with properties that improve strength and reliability.

At Simple Machining, we look beyond production costs. When we receive customer parts, we often reach out to clients to better understand design intent in order to deliver high-quality parts.

“Customer service and lead time were great. Team was quick to advise for DFM opportunities and material selections.”

Are your parts optimized? Our DFM service can help evaluate and get it ready for production!

Speed Constraints for Volume & Production Runs

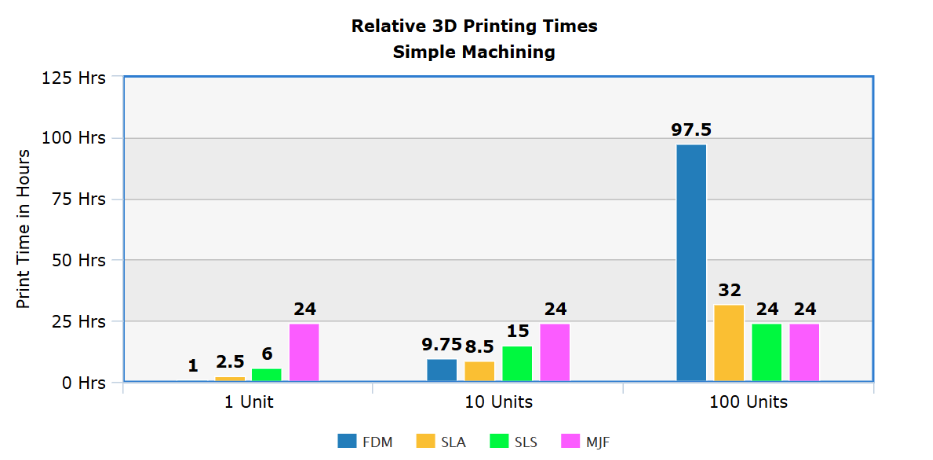

While FDM is great for individual prototypes, it becomes less efficient for larger production runs. Unlike other methods, FDM scales linearly. Each additional part increases print time proportionally, with minimal gains from eliminating setup cycles. Loading a full build plate offers negligible time savings.

As shown in this example (Figure 2), FDM remains cost-effective for quantities of 1 to 10 units, but quickly becomes less competitive at higher volumes. In contrast, processes like MJF can maintain the same print cycle time as long as all parts fit within the build volume, making them better suited for larger batch production.

Practical Applications of FDM 3D Printing

Prototyping and Product Development

FDM is well suited for quick, iterative development. It allows teams to evaluate form, fit, and function without waiting for tooling. With lead times as fast as one business day, multiple design versions can be tested in a single week. In one case, we supported a client through more than five design iterations in just a few days, something that would have been prohibitively expensive and time-consuming with traditional methods.

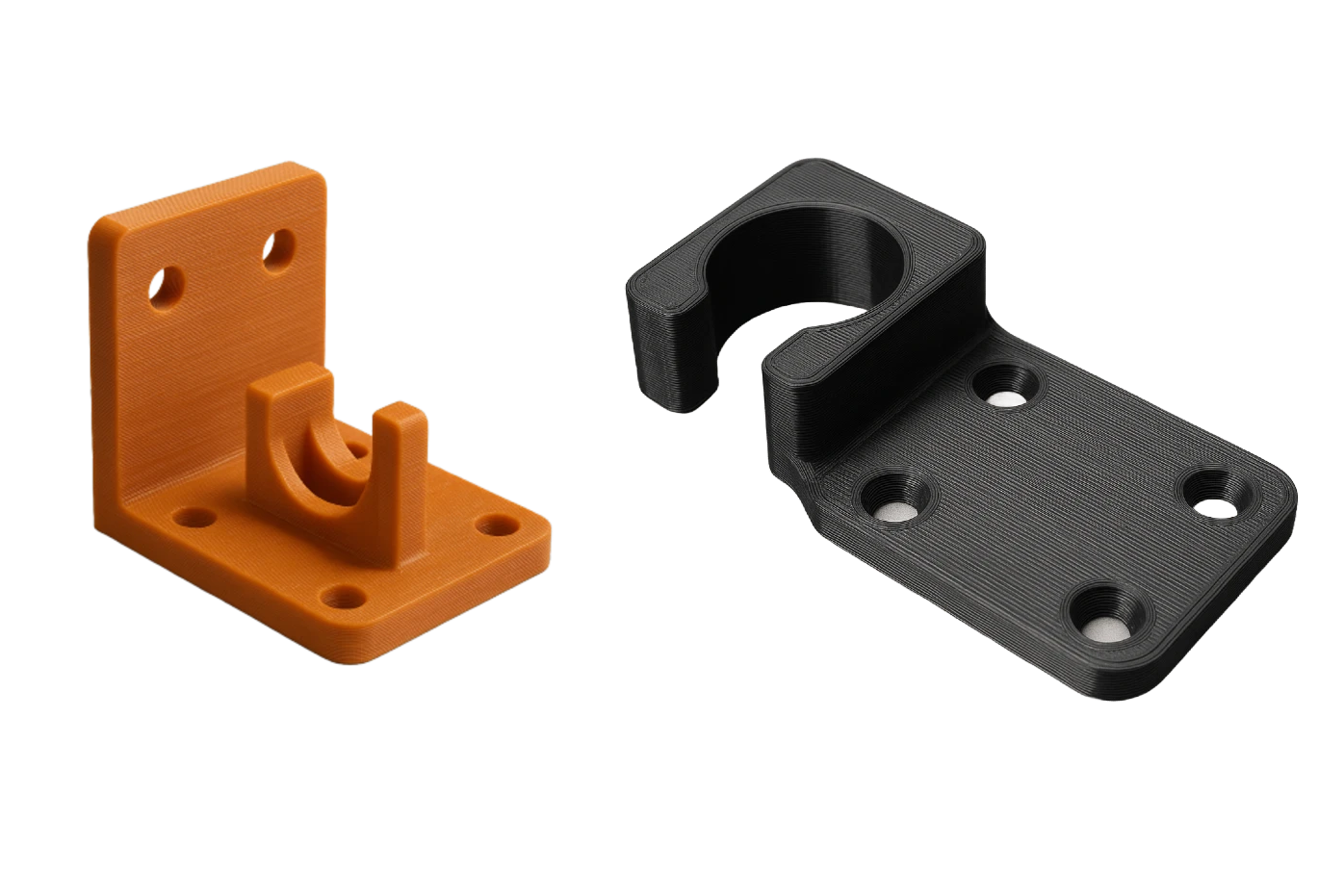

Jigs, Fixtures, and Tooling

FDM is commonly used to create one-off jigs and fixtures, helping to streamline assembly processes and improve production yields without expensive jigging costs. Custom tools can also be quickly designed and produced to fit specific parts or workflows. For manual assembly lines, these tools improve production reliability by ensuring consistency and standardization.

Short-Run Custom Production

While FDM is not the most efficient option for high-volume manufacturing, it can still be the best choice in certain cases. One common scenario is when parts are highly customized. Complex or unique geometries can be prohibitively expensive to produce through machining or molding, especially at lower quantities.

Because FDM has minimal upfront costs and uses relatively inexpensive materials such as PLA, ABS, ASA, etc, it is a practical choice for short production runs. For example, we’ve supported clients where FDM was the clear winner even for final production as the combination of design complexity, material needs, and low volume made alternative methods unreasonably expensive. In such cases where the end-use part is also produced with FDM, using the same material and process for prototyping alleviates uncertainty. This allows product designers to test the real-world performance of a part under final conditions, which leads to fewer surprises during production.

For industries like medical, robotics, and consumer products, where design flexibility and cost control are critical, FDM can be an efficient bridge from prototyping to low-volume production.

Ready to start 3D Printing? Create your account and upload a model

new customers get 20% off!

How to Choose Between FDM vs Alternative Processes

Choose FDM when:

- You need fast prototypes or are in the early stages of product development

- Your part has complex geometry that would be costly to produce using subtractive methods

- You want to avoid large upfront costs for molds or tooling – especially useful for SMB’s and startups

- Material availability and supply chain resilience are at the top of mind.

Consider alternatives like SLA, SLS, MJF, or CNC when:

- Your design requires tight tolerances or especially smooth surface finishes

- The part includes fine features or intricate geometry

- You are producing at higher volumes or need stronger, isotropic parts

Frequently Asked Questions About FDM

What materials can I use with FDM printing?

Common thermoplastics include PLA, ABS, and PETG. FDM also supports specialty filaments like rubberized TPU 95A for flexibility, and reinforced options such as PLA-CF, which is PLA reinforced with carbon fiber for added strength and stiffness.

Is FDM 3D printing suitable for production-level parts?

Yes, for low-volume production runs and non-critical or non-load-bearing components. For high-performance parts or larger production volumes, we recommend exploring CNC machining, injection molding, or other additive manufacturing methods. Learn more about our 3D Printing Service or CNC Milling Service.

How does FDM compare to SLA and CNC machining?

FDM is typically more accessible and cost-effective, especially for early-stage development. However, other additive manufacturing processes, such as SLA, offer higher resolution, and CNC provides superior strength and precision for demanding applications. Not sure what to choose? Reach out here

Key Takeaways

- FDM is fast, accessible, and affordable

- Great for prototyping, custom tools, and low-volume parts

- Lower detail and strength than other options

- Best when speed and cost are more important than finish or tolerances

Want to learn how FDM can fit into your production workflow? Contact the Simple Machining team today for guidance tailored to your needs.

Looking for more insights?

Sign up for the newsletter:

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th

Scaling Without Risk: On-Demand Manufacturing for Startups and SMBs

Read the Article 6 minute read

6 minute read

August 25th

August 25th