- Home

- About Us

-

Industries

-

Resources

- Contact Us

DFAM Done Right: A Practical Playbook for Modern Product Development

Published on: July 28, 2025

By: The Simple Machining Team

Design for Manufacturing and Assembly (DFMA) is more than just an industry buzzword, it’s a set of practical guidelines to help ensure your CAD models actually translate into manufacturable parts.

At its core, DFMA ensures that your CAD models aren't just theoretically sound but also cost-effective, producible, and scalable using real-world manufacturing processes like CNC machining and 3D printing.

For SMBs and startups with tight timelines and budgets, mastering DFM is critical to reduce expenses or even entire reworks.

In this guide, you'll learn:

- What is DFM?

- Why it matters for engineers and procurement professionals

- Key design principles for manufacturing ready parts

- Process-specific DFM strategies for CNC and additive methods

- Common pitfalls that raise costs

- How Simple Machining supports DFMA-ready design

Read our guide: How Overlooking Tolerances Can Sink Your Machining Project

What Is Design for Manufacturability?

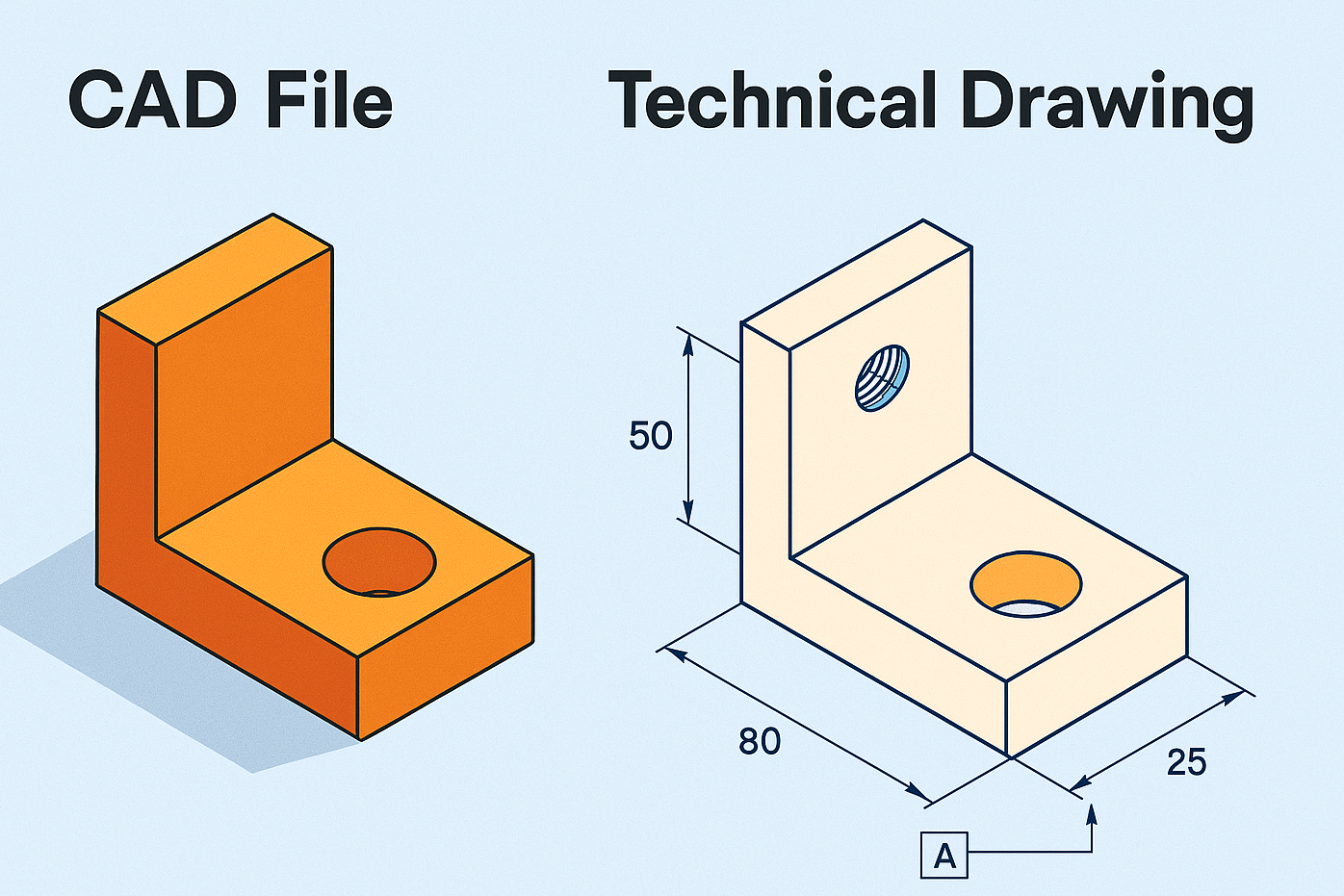

Design for Manufacturability (DFM), including its extensions such as Design for Manufacturing and Assembly (DFMA) and Design for Additive Manufacturing (DFAM), is the practice of optimizing product designs to align with the capabilities and limitations of specific manufacturing methods. While designs may start idealistically in CAD, it doesn’t matter if they're not manufacturable or are prohibitively expensive to produce.

Simply put, the goal of DFM is:

- Ensure the design can be manufactured in the desired process.

- Improve production reliability.

- Reduce production costs while maintaining functionality.

Why DFM Matters for Product Development and Procurement Teams

Startups

Startups operate under tight deadlines and limited budgets, making every design decision count. DFM helps reduce the risk of costly redesigns by catching manufacturability issues early. It prevents overly tight tolerances, complex features, or unprintable geometries that could derail a prototype or delay production. By aligning your design with real-world manufacturing constraints from the start, you keep iteration cycles lean, accelerate prototyping, and move faster toward market launch.

Procurement Teams

For procurement professionals, DFM streamlines the entire sourcing process. Well-optimized designs result in more accurate quotes, predictable lead times, and fewer surprises during manufacturing. This is especially critical where variability can quickly impact budgets, as per-unit costs are higher with low-volume or prototype production. DFM reduces back-and-forth with suppliers and enables better forecasting, supplier selection, and project planning.

Core Design for Manufacturing Principles

Simplify Geometry

Avoid unnecessary contours, undercuts, tight tolerances, or fragile features that complicate tooling or increase print time.

Minimize Part Count

Combine parts where possible to reduce assembly time and potential failure points.

Standardize Features

Use industry-standard hole sizes, thread types, and material specs to streamline part sourcing and fabrication. If you use the industry standard, suppliers are more likely to provide accurate parts.

Design for Tooling Access

Ensure that all features are accessible by cutting tools or printer heads. An example of this are geometries internal to a part which cannot be reached by

Plan for Post-Processing

Consider finishing steps like deburring, support removal, or heat treatment from the start. Post processing by nature will affect tolerances and features. If you paint your parts, you have added a coating which now changes the external dimension. This combined with machining tolerance could make the part unusable

Use Tolerances Strategically

Apply tight tolerances only where functionally necessary to reduce inspection costs and machining time. For subtractive manufacturing especially, reducing the number of tool changes and using the largest end mill possible to reduce cutting times.

DFM for CNC Machining

- Avoid deep narrow pockets—they require slow toolpaths and extra setups

- Keep wall thickness consistent

- Minimize custom tooling by utilizing standard features

- Choose material based on machinability (e.g., aluminum over titanium when possible)

Coming Soon: A Step by Step Guide to DFM for CNC Machining

Design for Additive Manufacturing (DFAM)

- Design self-supporting features to reduce scaffolding

- Orient parts to reduce warping and minimize defect risk

- Use internal lattices or voids to reduce weight without sacrificing strength

- Account for shrinkage, anisotropy, and layer adhesion when selecting materials

Coming Soon: read our step by step, detailed DFAM Guide

Common DFM Mistakes That Increase Manufacturing Costs

Overengineering: Adding features that are difficult or unnecessary to produce.

Ignoring Tooling Constraints: Designing parts that require multi-axis setups or special fixturing when it is not absolutely required.

Misaligned Mating Features: Assemblies that don’t account for real-world tolerance stack-up. Read more about tolerance stacking and tips to avoid it.

Skipping Early Reviews: Waiting until the quote phase to identify manufacturability issues. We really appreciate when customers reach out early in the process and ask about optimization. This gives both parties confidence when designing/producing parts.

How to Apply DFM in Your Workflow

Embed DFM Early

Use DFM as a lens during the CAD phase, not after. Whenever possible, determine which process you will use to manufacture this and design with that in mind. This will help refine designs early, rather than spending engineering hours on a design that is ultimately unmanufacturable.

Collaborate with Manufacturers

Share early models and gather feedback before prototyping. We appreciate when clients reach out with questions early, as it leads to better outcomes and gives you confidence that your design is manufacturable from the start.

Use DFM Software Tools

Platforms like SolidWorks and Fusion 360 offer built-in checks. These offer a good, high-level analysis for quick remediation.

Iterate with Purpose

Each prototype should bring you closer to a production-ready part. Work with your manufacturing partner to validate feasibility, check material behavior, and confirm tolerance performance.

How Simple Machining Supports Manufacturable Designs

We offer DFM reviews as part of our quoting and pre-production services for both CNC machining and 3D printing. Our feedback loop ensures your parts are ready for manufacturing without surprises. From wall thickness advice to tolerance clarification, our team supports you at every step. Online orders also undergo built-in DFM checks, as well as a manual review, where a team member approves each part before production.

Need deeper support? We also offer standalone DFM services by process. If you have a model but aren't sure how to proceed, contact us for a one-price quote — no hourly billing.

Learn more about our CAD Design and DFM services here.

Final Thoughts

Designing for manufacturability means making smarter, production-ready decisions from the start. Without DFM, you risk longer design cycles, reworks, and expensive builds. Whether you're prototyping a single part or scaling to production, Simple Machining helps prepare your designs for real-world manufacturing.

Need help making your parts ready for CNC or 3D printing? Contact Simple Machining for DFM-optimized, on-demand manufacturing you can trust.

Disclaimer

The content appearing on this webpage is for informational purposes only. Simple Machining makes no representation or warranty of any kind, be it expressed or implied, as to the accuracy, completeness, or validity of the information. Any performance parameters, geometric tolerances, specific design features, quality and types of materials, or processes should not be inferred to represent what will be delivered by Simple Machining. Buyers seeking quotes for parts are responsible for defining the specific requirements for those parts. Please refer to our terms and conditions for more information.

Looking for more insights?

Sign up for the newsletter:

Scaling with On-Demand Manufacturing for Startups and SMBs

Read the Article 5 minute read

5 minute read

September 15th

September 15th